rferguson61

Well-Known Member

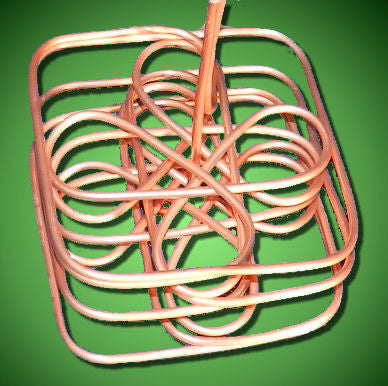

So thinking about making an immersion wort chiller...but not the typical style of a bunch of coils. It will be criss-crossing layers to get the most surface area covered...therefore a lot of saudered fittings. I have three questions...first, polishing (which is essentially putting lots of super tiny scratches in the pipe) is that a good idea? Second, would submersing the chiller in the last 10 minutes of the boil impart any metallic flavors into the beer? Third, would stainless steel be a better material?