Hello fellow brewers!

I decided to turn my shed into a brew house.

This will be a summer project, but I am planning and buying materials now.

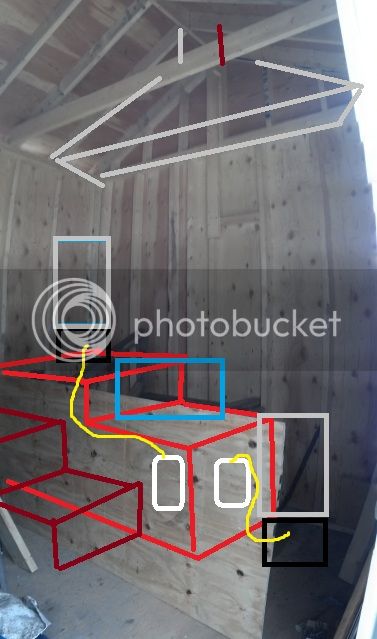

This is my shed..

I am planning my own version of the Brutus Ten build from the November 2007 issue of brew your own.

I am trying to gather all the stuff I need but I have questions about a few things, and could use so input..

This maybe a lengthy read and a lot of my inner thoughts. (LOL) but I could really use the help/ guidance with this build to do it right.

Here is my plan so you can see where I am at and need help.

Here is my vision.

I am going to have a electrician friend help me wire my shed.

Wired with a ceiling light and a few wall plugs.

Custom 3 burner brew stand (I weld using my mig welder)

Still deciding on what burners to use.

Also I need LOTs of input on safety of running burners inside a shed.

My plan was to have vent taking steam out and then keep door open so I don't pass out. lol ok well . you know what I mean.

I had a thought to add 2 windows to it for light and maybe more vents if needed.

3 Keggle system as I have 3 kegs already.

I want to buy this nice Stainless steel hop spider I found to try to keep the hops out of plate chiller and fermentor.

Some kind of hood vent to suck moisture from the room.

(I need help on this.)

Thinking of some kind of rectangle galvanized duct with fan and pipe going out back upper shed wall.

March pumps, need 2 not sure what the best value is on these is. Any help in my purchase is appreciated. (keeping lowest cost/best value/ best quality for that value in mind)

I need 2 temp controllers as the Brutus used 2 LOVE controllers.

But I made my own temp controlled fermentor and used a STC-1000 temp controller from HK and it works great. So I wonder if I could use 2 of those instead to save over 100$???

Insulate walls build shelves.

I want to buy a plate chiller and see tons on ebay at good deals but not sure which ones are good.

I like the ones that have the fittings I want on them already so i don't have to buy additional fittings.

I have been reading a lot about chilling and idea's and have a few questions.

If I use a plate chiller and re-circulate the wort through the chiller (I want to put the chiller in ice bath and pump ice water through it as well) how will the temp of the boil pot effect the cooling. (also trying to leave the cold break in the kettle not fermentor)

I tried to cool my keg batch once before with using immersion chiller and the kegs metal was so hot for so long it took forever to cool. So after that day i pick up the whole keg and put in a Tupperware full of ware and ice to cool the keg then my immersion chiller worked better... Will using a plate chiller and recirculating the wort back into the kettle cool the metal kettle as well?

I am really excited and motivated on this custom brew house so any input is appreciated.

My final goad is to escape to man brew town and have a fun time brewing.

I have a upright TRUE RC COLA refrigerator I use as a temp controlled fermenting chamber I plan on putting out in the shed.

I envision cool beer posters and hot girl calenders.

I want to incorporate this mini fridge I have with some brews in it.

A TV (probably just one of my old tube TV's that no one uses anymore lol)

I want to get a HDTV antenna and just use that as well. (I don't pay for cable it costs too much) So I can at least use that to brew on gameday's

Like I said really excited about this and that's why I am reaching to all you homebrew pros for help.

thanks all!

Brian

I decided to turn my shed into a brew house.

This will be a summer project, but I am planning and buying materials now.

This is my shed..

I am planning my own version of the Brutus Ten build from the November 2007 issue of brew your own.

I am trying to gather all the stuff I need but I have questions about a few things, and could use so input..

This maybe a lengthy read and a lot of my inner thoughts. (LOL) but I could really use the help/ guidance with this build to do it right.

Here is my plan so you can see where I am at and need help.

Here is my vision.

I am going to have a electrician friend help me wire my shed.

Wired with a ceiling light and a few wall plugs.

Custom 3 burner brew stand (I weld using my mig welder)

Still deciding on what burners to use.

Also I need LOTs of input on safety of running burners inside a shed.

My plan was to have vent taking steam out and then keep door open so I don't pass out. lol ok well . you know what I mean.

I had a thought to add 2 windows to it for light and maybe more vents if needed.

3 Keggle system as I have 3 kegs already.

I want to buy this nice Stainless steel hop spider I found to try to keep the hops out of plate chiller and fermentor.

Some kind of hood vent to suck moisture from the room.

(I need help on this.)

Thinking of some kind of rectangle galvanized duct with fan and pipe going out back upper shed wall.

March pumps, need 2 not sure what the best value is on these is. Any help in my purchase is appreciated. (keeping lowest cost/best value/ best quality for that value in mind)

I need 2 temp controllers as the Brutus used 2 LOVE controllers.

But I made my own temp controlled fermentor and used a STC-1000 temp controller from HK and it works great. So I wonder if I could use 2 of those instead to save over 100$???

Insulate walls build shelves.

I want to buy a plate chiller and see tons on ebay at good deals but not sure which ones are good.

I like the ones that have the fittings I want on them already so i don't have to buy additional fittings.

I have been reading a lot about chilling and idea's and have a few questions.

If I use a plate chiller and re-circulate the wort through the chiller (I want to put the chiller in ice bath and pump ice water through it as well) how will the temp of the boil pot effect the cooling. (also trying to leave the cold break in the kettle not fermentor)

I tried to cool my keg batch once before with using immersion chiller and the kegs metal was so hot for so long it took forever to cool. So after that day i pick up the whole keg and put in a Tupperware full of ware and ice to cool the keg then my immersion chiller worked better... Will using a plate chiller and recirculating the wort back into the kettle cool the metal kettle as well?

I am really excited and motivated on this custom brew house so any input is appreciated.

My final goad is to escape to man brew town and have a fun time brewing.

I have a upright TRUE RC COLA refrigerator I use as a temp controlled fermenting chamber I plan on putting out in the shed.

I envision cool beer posters and hot girl calenders.

I want to incorporate this mini fridge I have with some brews in it.

A TV (probably just one of my old tube TV's that no one uses anymore lol)

I want to get a HDTV antenna and just use that as well. (I don't pay for cable it costs too much) So I can at least use that to brew on gameday's

Like I said really excited about this and that's why I am reaching to all you homebrew pros for help.

thanks all!

Brian