bracehelton

Member

- Joined

- Mar 26, 2013

- Messages

- 21

- Reaction score

- 6

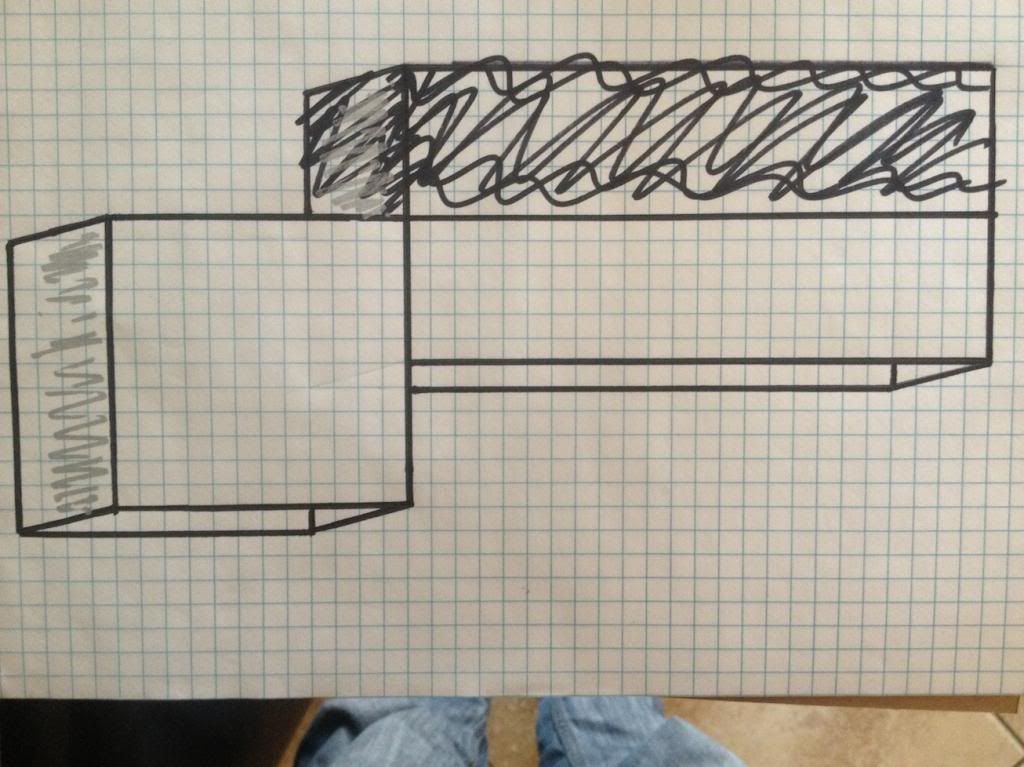

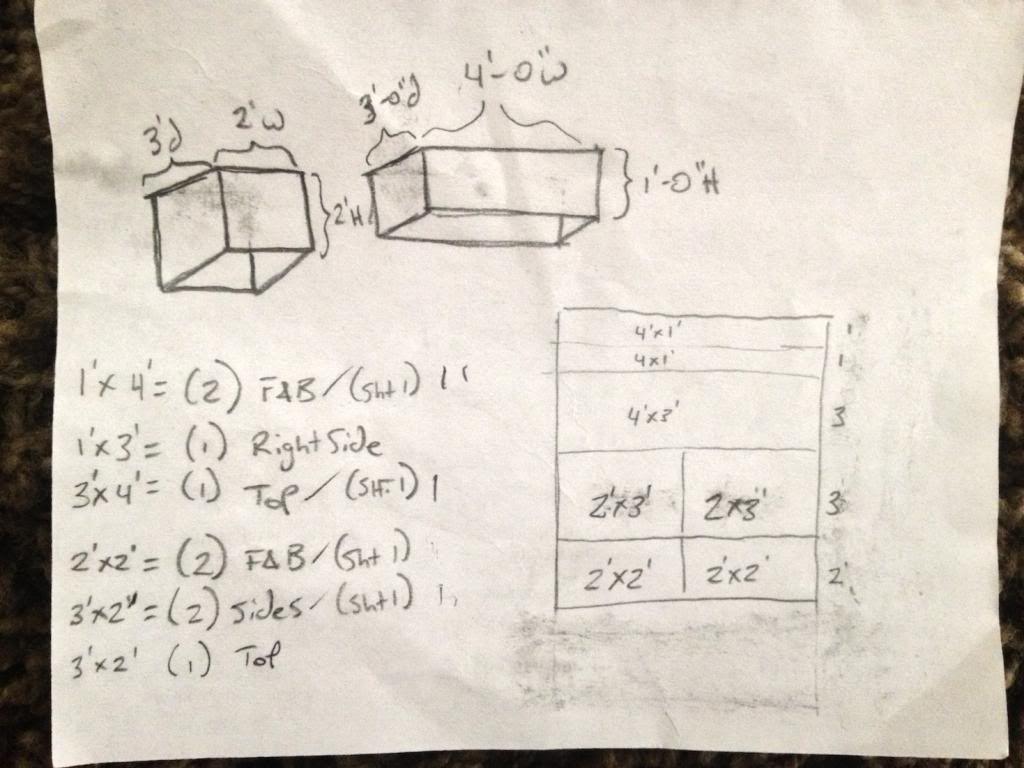

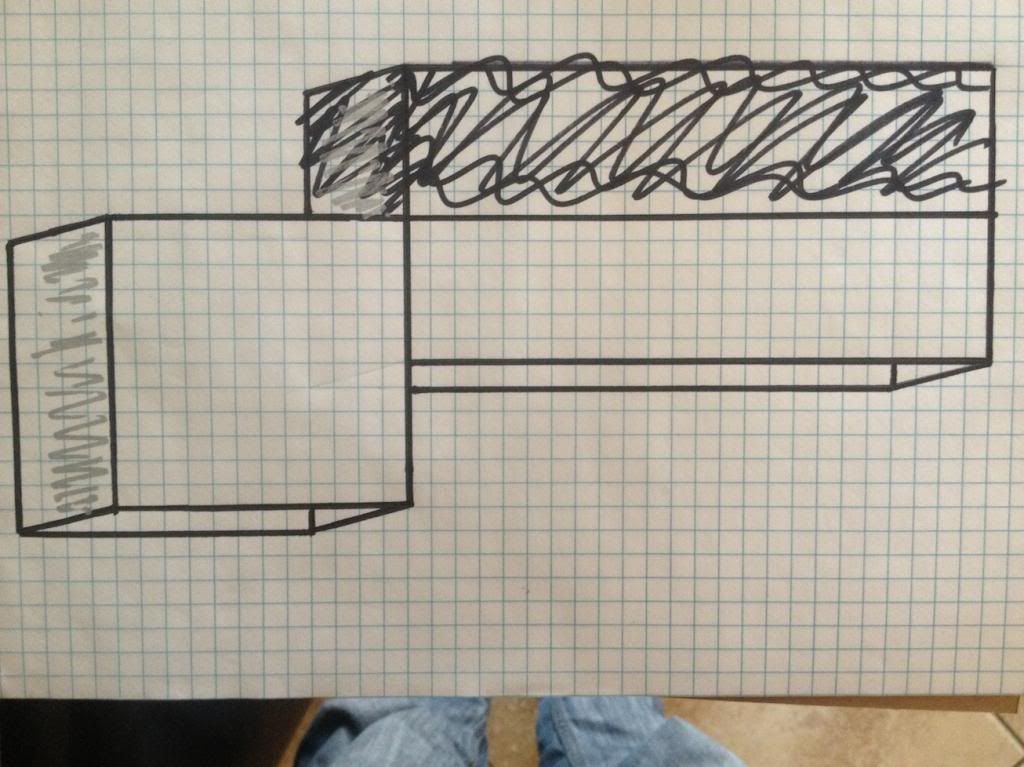

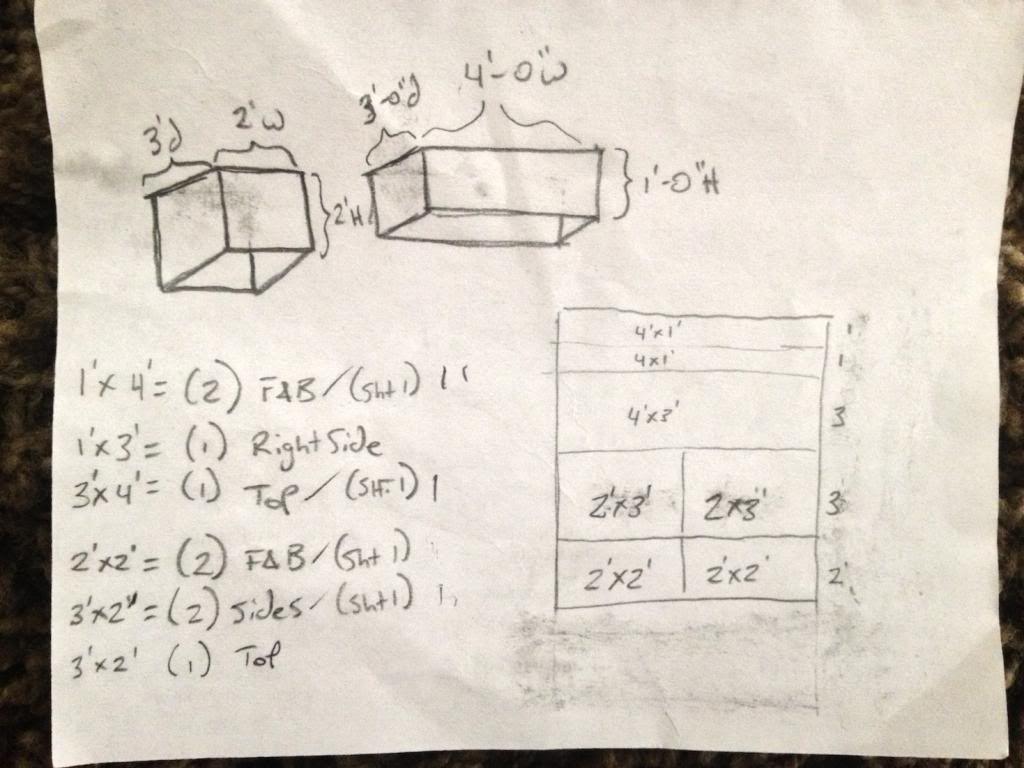

I just put in my order for the Sabco Brew Magic. I am trying to get a head start preparing my Bru-Room. I also just purchased an 8" CAP Valuline Inline Fan. Im hoping it turns out to be good. It seems that the safe bet is the Vortex but I watched a bunch of youtube videos one of which compared the Vortex and Valuline. The Valuline did pretty well. I dont think I will need the full 700+ CFM but I also got a speed controller to be able to find a good sound/suction balance. I went to a local steel shop and bought some supplies to make a custom range hood. I was also going to try to implement some Condensate Hood Gutters around the perimeter. Here is a quick sketch of what I had in mind. I am going to break it up into 2 section with valves to let the vent directly above the boiler go at full blast with the vent over the HLT and MLT turned off when not in use. Let me know if anyone has any advice/comments. Thanks.