headfullahops

Well-Known Member

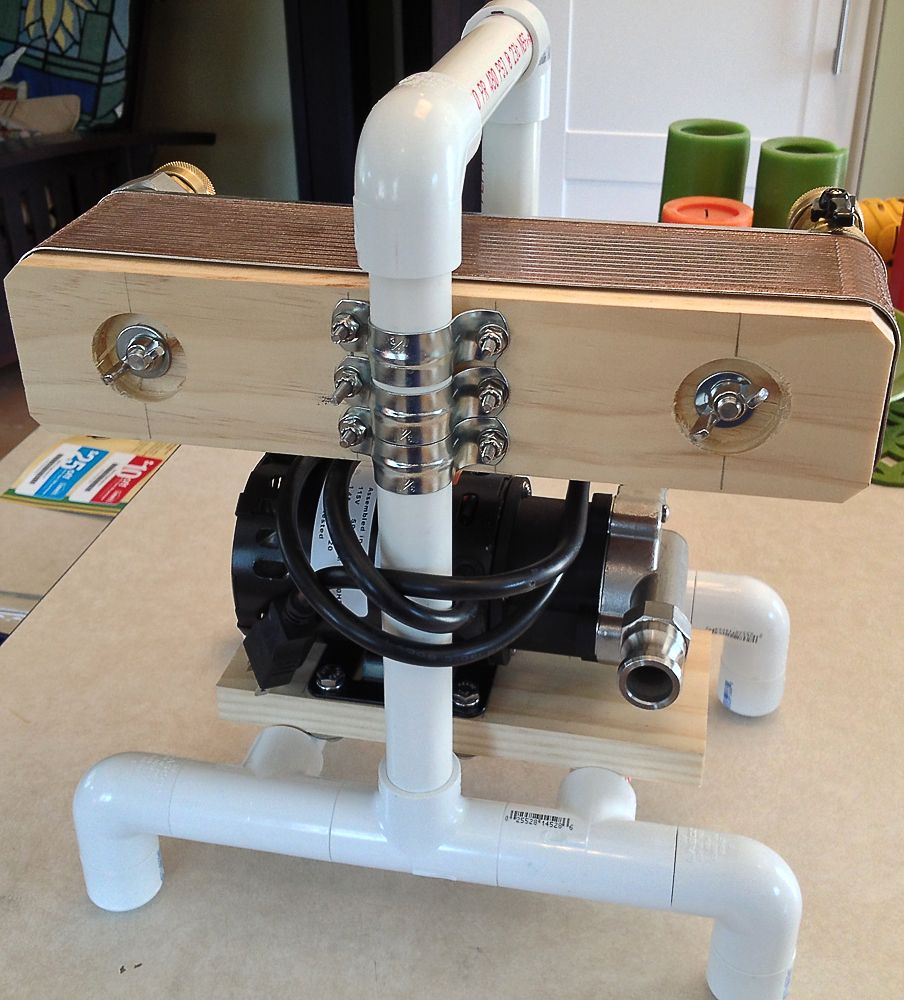

I live in Michigan and we get some fairly cold and snowy winters. Even though I do most of my brewing outside on a propane burner, this hasn't stopped me from brewing year-round. That being said, up to yesterday (April 26th), I haven't brewed since mid-October because of my work schedule. I did, however, use the time off to collect some new gear and do some pretty in-depth brainstorming on how I want to use it and update my process.

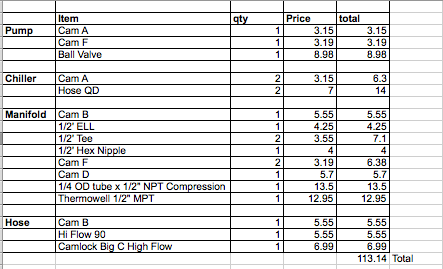

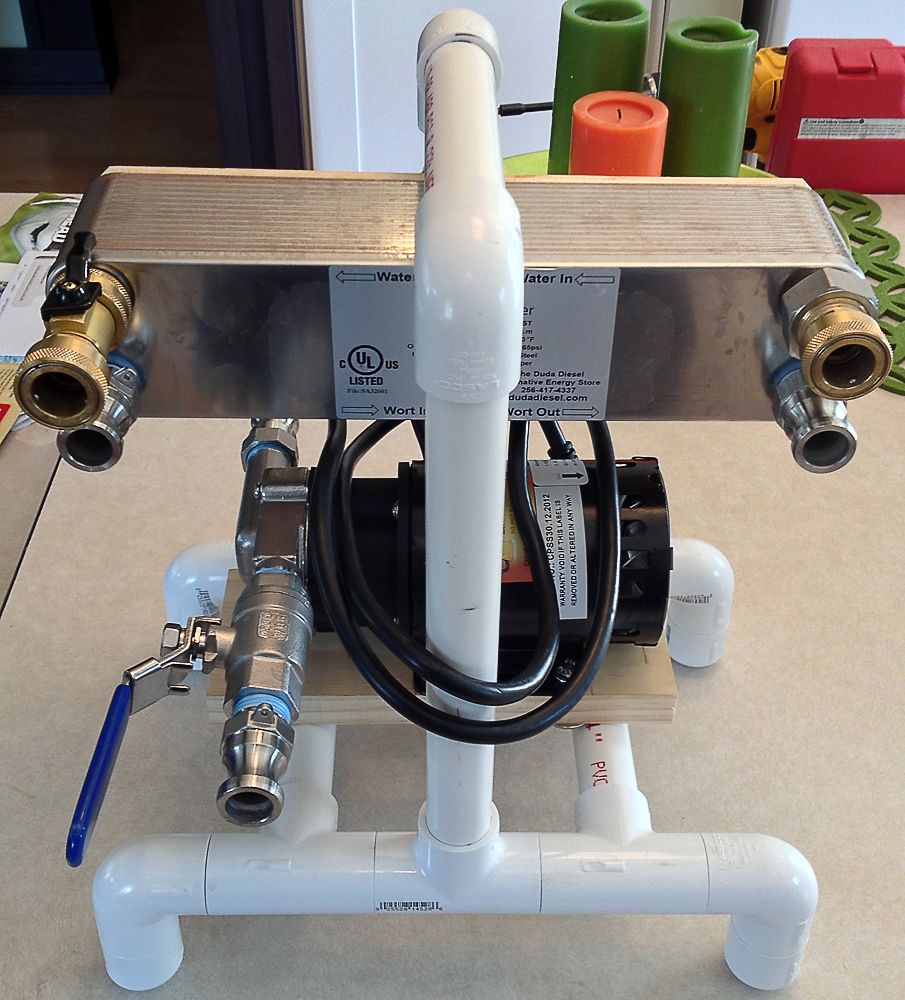

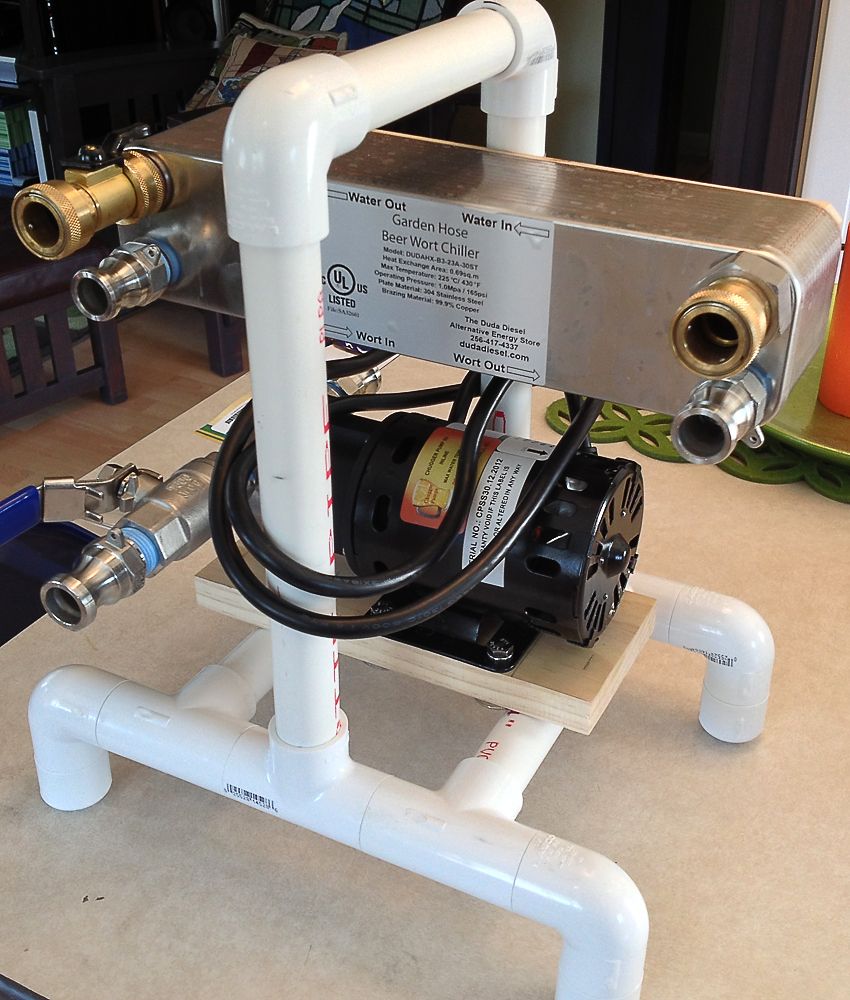

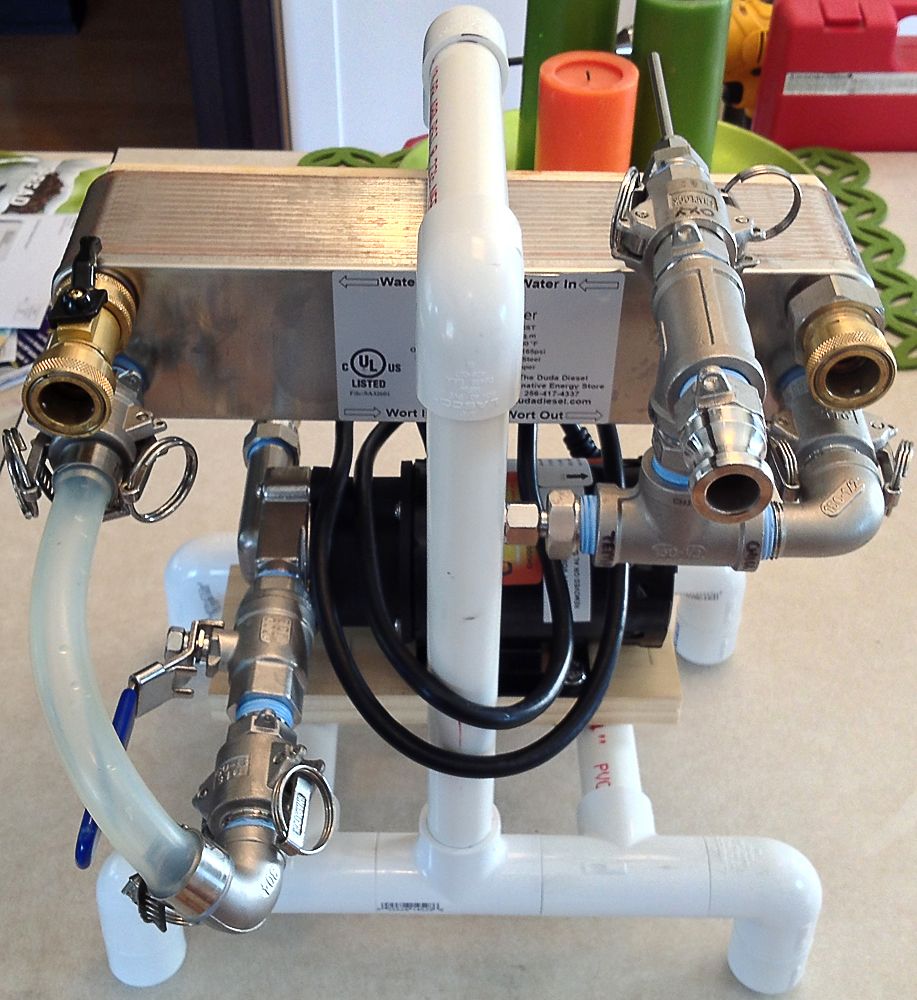

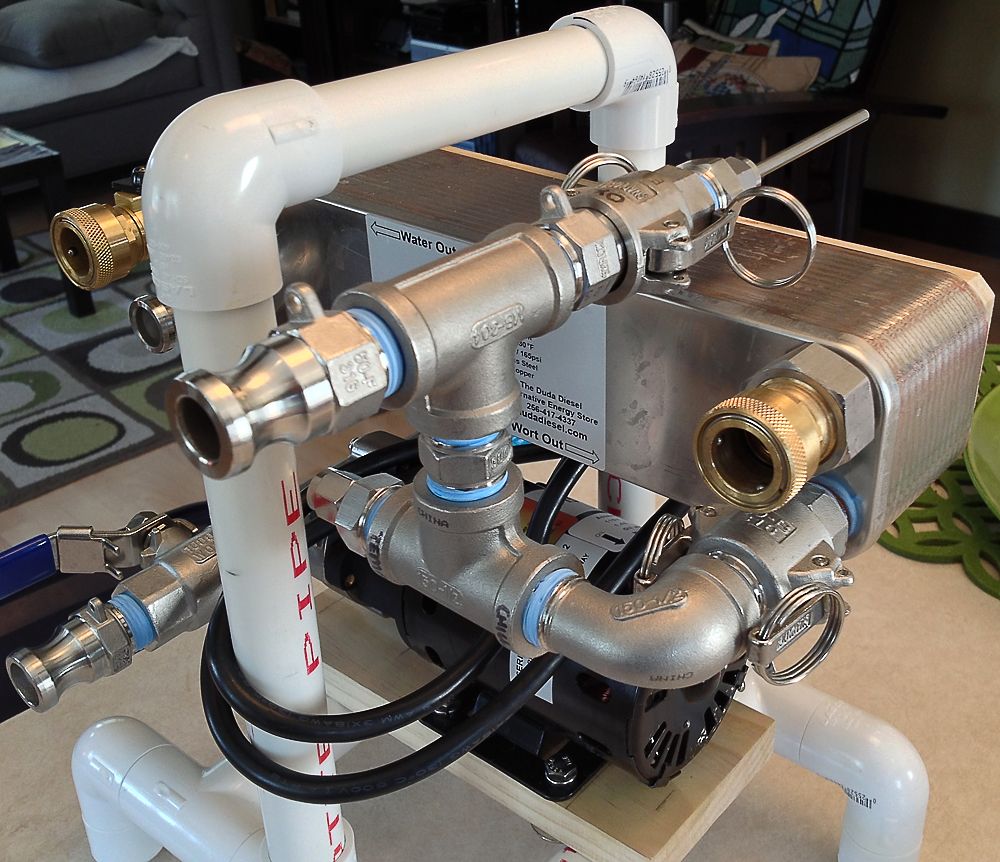

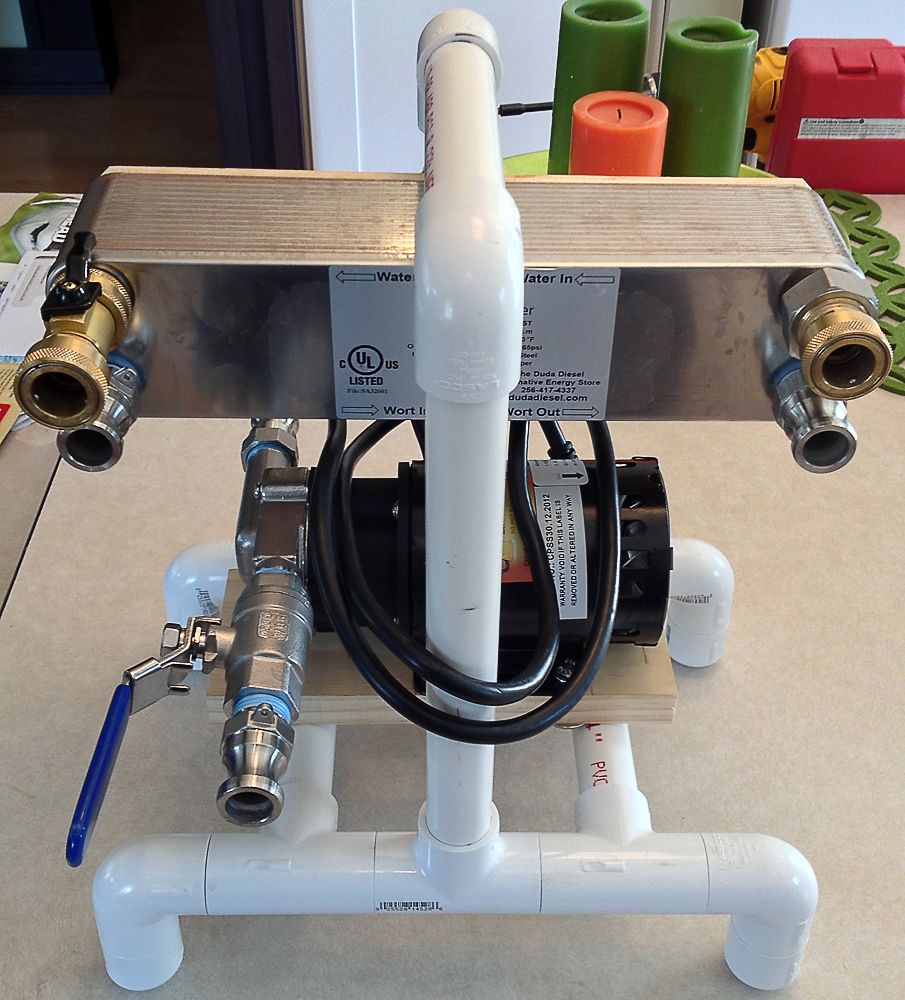

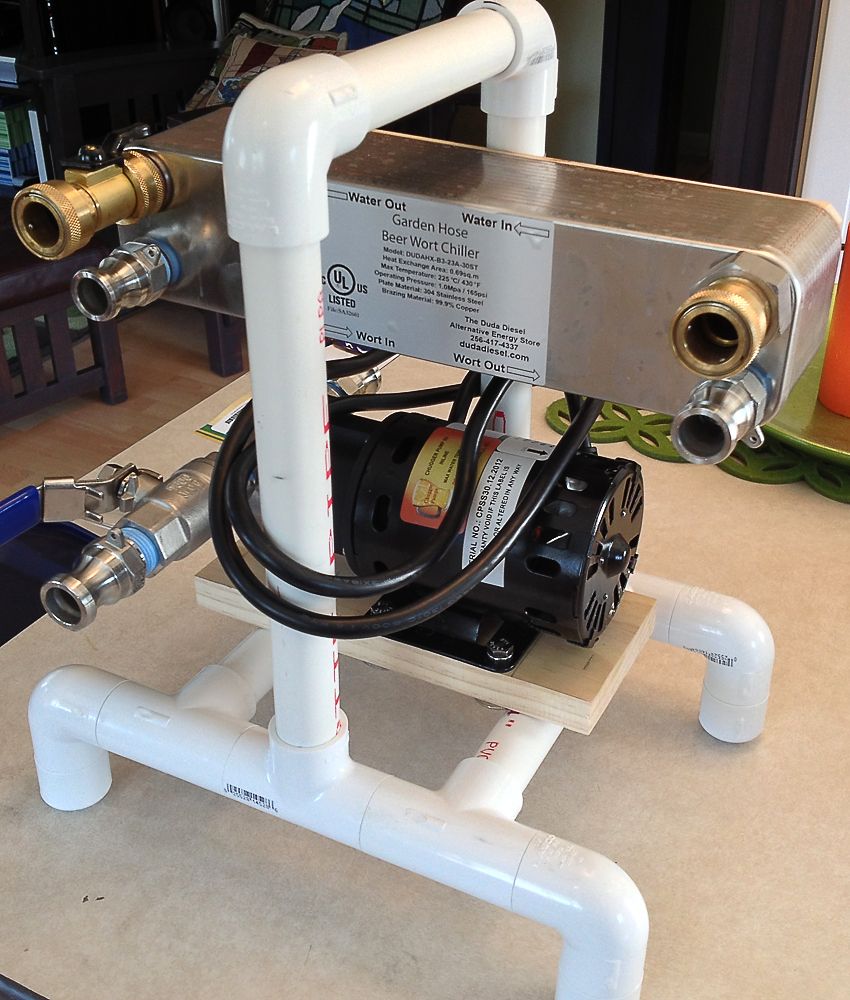

The thing that was the biggest change for me was incorporating a Chugger pump and 30-plate chiller from Bobby_M at brewhardware.com into my brewery. I don't have a brew stand/sculpture or really any place to store something like that if I did, so I need my gear to be modular enough for one person to haul up/down to/from my basement as well as condensed enough that I'm not spending all day on the stairs (if that makes sense).

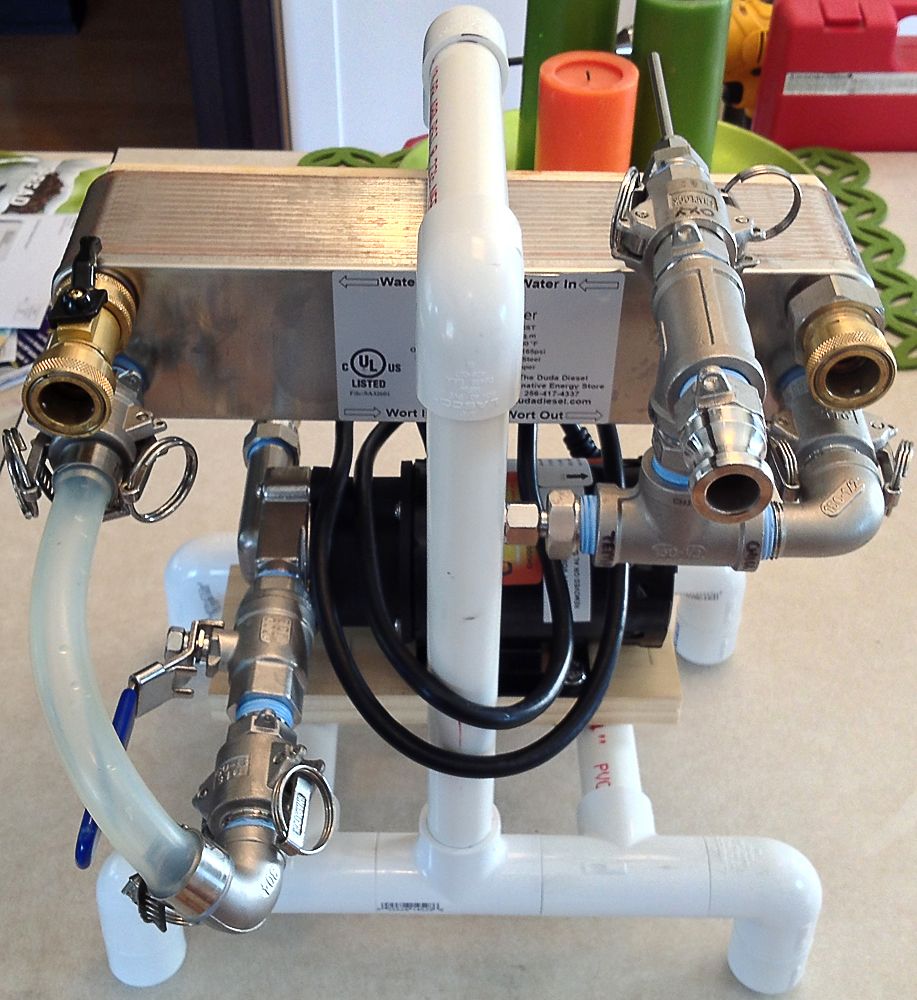

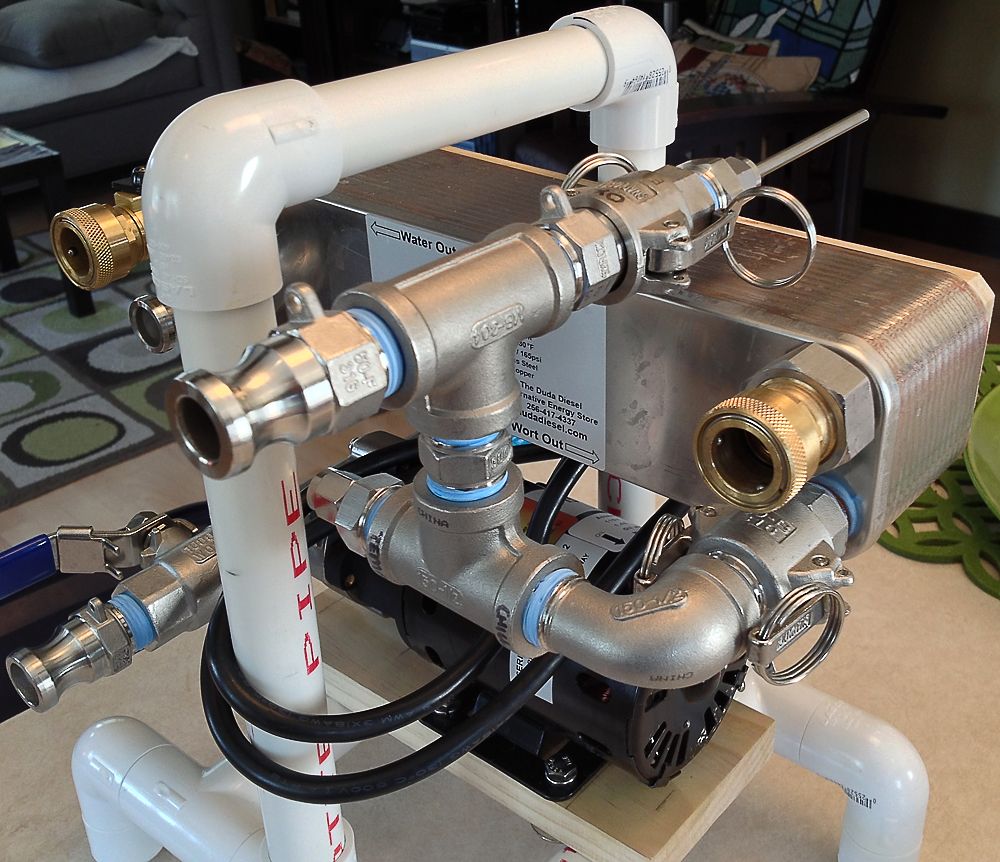

So, I wanted to come up with a cradle/carrier that would incorporate the plate chiller and pump in a way that would take as little time to set up, sanitize, clean, tear down, etc. and still be able to use the pump at other points in the process without using tools and teflon tape. All that to say, I was very intrigued by the concept/design of the Sabco Chill Wizard and at the same time very turned off by the cost. Here's what I came up with:

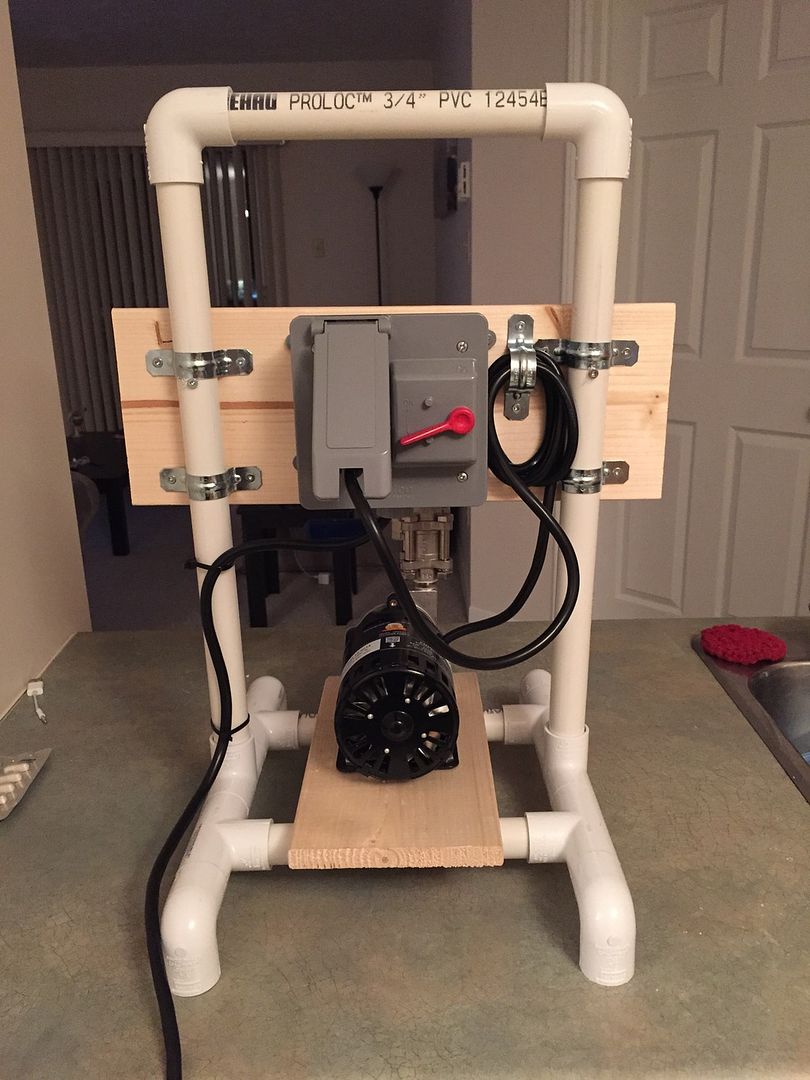

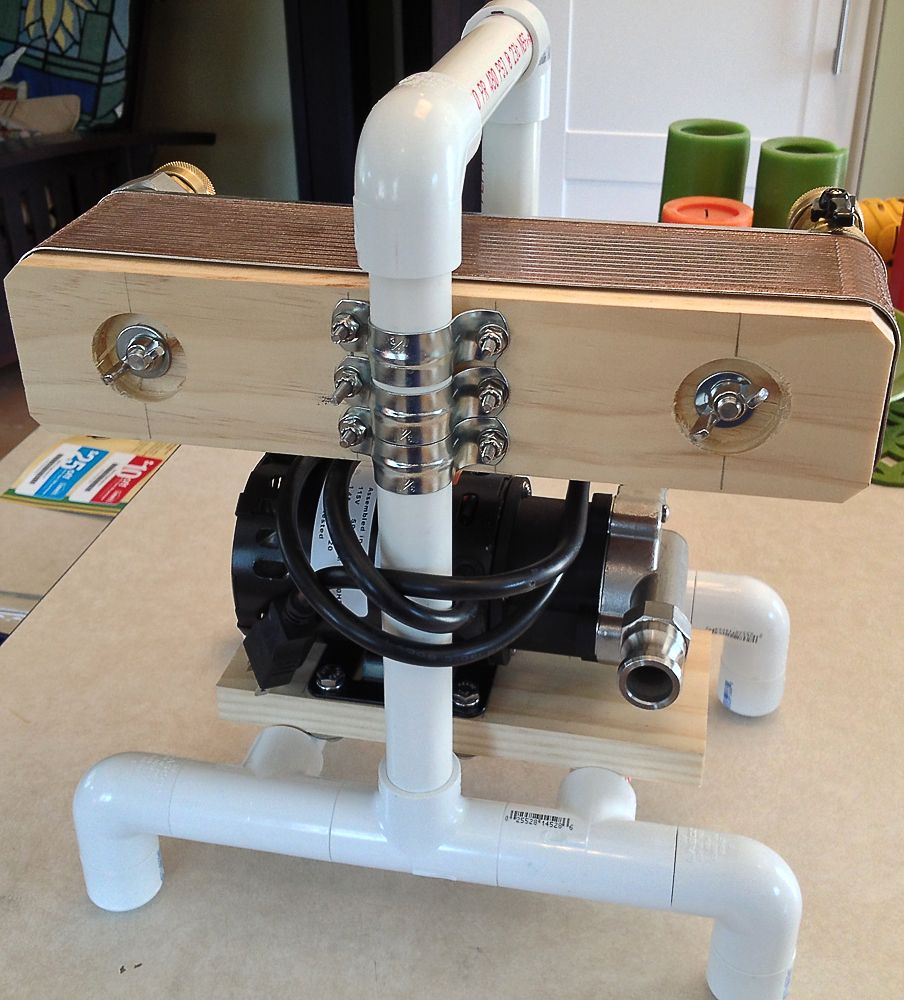

A 3/4" PVC cradle/carrier with the pump and chiller mounted to 3/4" finish pine boards mounted to the PVC with pipe straps.

All connections on camlock QD's (hose QD's from Ace Hardware) plumbed with 1/2" ID silicone tubing.

1/2" MPT fitting on out-side of chiller that incorporates a digital thermometer and inline oxygen stone.

The thing that was the biggest change for me was incorporating a Chugger pump and 30-plate chiller from Bobby_M at brewhardware.com into my brewery. I don't have a brew stand/sculpture or really any place to store something like that if I did, so I need my gear to be modular enough for one person to haul up/down to/from my basement as well as condensed enough that I'm not spending all day on the stairs (if that makes sense).

So, I wanted to come up with a cradle/carrier that would incorporate the plate chiller and pump in a way that would take as little time to set up, sanitize, clean, tear down, etc. and still be able to use the pump at other points in the process without using tools and teflon tape. All that to say, I was very intrigued by the concept/design of the Sabco Chill Wizard and at the same time very turned off by the cost. Here's what I came up with:

A 3/4" PVC cradle/carrier with the pump and chiller mounted to 3/4" finish pine boards mounted to the PVC with pipe straps.

All connections on camlock QD's (hose QD's from Ace Hardware) plumbed with 1/2" ID silicone tubing.

1/2" MPT fitting on out-side of chiller that incorporates a digital thermometer and inline oxygen stone.