// ======================================================= Includes =======================================================

#include <util/delay.h> // Using _delay_ms(#) rather than delay(#) saves 146 bytes of sketch size!

// ================================================== User-Specific Data ==================================================

#define Sensor1 "Carboy_1_Temperature" // Enter whatever you wish to call your first sensor inside the double quotes

#define Sensor2 "Ambient_Temperature" // Enter whatever you wish to call your second sensor inside the double quotes

#define FEEDID "102607" // Enter the feed ID assigned to you by Cosm.com inside the double quotes

#define APIKEY "xxxxxxxxD0kjGte5FxxxxxxxxxCSAKxva3hwZ3hCxxxxxxxx" // Enter the feed APIKEY assigned to you by Cosm.com inside the double quotes

#define USERAGENT "Test" // Enter

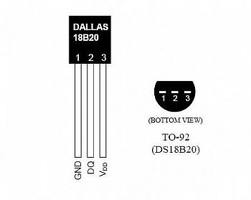

const uint8_t pin = 3; // The pin that the data pin of the DS18B20s is connected to

const uint8_t Sensor[2][8] = {{ 0x28, 0xE0, 0xF7, 0x83, 0x04, 0x00, 0x00, 0x0F }, // Thermowell sensor

{ 0x28, 0x68, 0xEF, 0x7D, 0x04, 0x00, 0x00, 0x62 }}; // Ambient room air sensor

#define DELAY 5000 // The delay in milliseconds between sensor readings; the code below takes around a second to run total

// ===================================================== Definitions ======================================================

#define PIN_TO_BASEREG(pin) (portInputRegister(digitalPinToPort(pin)))

#define PIN_TO_BITMASK(pin) (digitalPinToBitMask(pin))

#define IO_REG_TYPE uint8_t

#define IO_REG_ASM asm("r30")

#define DIRECT_READ(base, mask) (((*(base)) & (mask)) ? 1 : 0)

#define DIRECT_MODE_INPUT(base, mask) ((*(base+1)) &= ~(mask))

#define DIRECT_MODE_OUTPUT(base, mask) ((*(base+1)) |= (mask))

#define DIRECT_WRITE_LOW(base, mask) ((*(base+2)) &= ~(mask))

#define DIRECT_WRITE_HIGH(base, mask) ((*(base+2)) |= (mask))

#define STARTCONVO 0x44 // Tells device to take a temperature reading and put it on the scratchpad

#define READSCRATCH 0xBE // Read EEPROM

#define TEMP_LSB 0

#define TEMP_MSB 1

#define DEBUG 0 // Controls the inclusion or exclusion of serial debug information; 0 for no serial output 1 for serial output

// AVRJazz Mega328 SPI I/O

#define SPI_PORT PORTB

#define SPI_DDR DDRB

#define SPI_CS PORTB2

// Wiznet W5100 Op Code

#define WIZNET_WRITE_OPCODE 0xF0

#define WIZNET_READ_OPCODE 0x0F

// Wiznet W5100 Register Addresses

#define MR 0x0000 // Mode Register

#define GAR 0x0001 // Gateway Address: 0x0001 to 0x0004

#define SUBR 0x0005 // Subnet mask Address: 0x0005 to 0x0008

#define SAR 0x0009 // Source Hardware Address (MAC): 0x0009 to 0x000E

#define SIPR 0x000F // Source IP Address: 0x000F to 0x0012

#define RMSR 0x001A // RX Memory Size Register

#define TMSR 0x001B // TX Memory Size Register

#define S0_MR 0x0400 // Socket 0: Mode Register Address

#define S0_CR 0x0401 // Socket 0: Command Register Address

#define S0_IR 0x0402 // Socket 0: Interrupt Register Address

#define S0_SR 0x0403 // Socket 0: Status Register Address

#define S0_DIPR 0x040C // Socket 0: Destination IP Address: 0x040C to 0x040F

#define S0_DPORT 0x0410 // Socket 0: Destination Port: 0x0410 to 0x0411

#define S0_PORT 0x0404 // Socket 0: Source Port: 0x0404 to 0x0405

#define SO_TX_FSR 0x0420 // Socket 0: Tx Free Size Register: 0x0420 to 0x0421

#define S0_TX_RD 0x0422 // Socket 0: Tx Read Pointer Register: 0x0422 to 0x0423

#define S0_TX_WR 0x0424 // Socket 0: Tx Write Pointer Register: 0x0424 to 0x0425

#define S0_RX_RSR 0x0426 // Socket 0: Rx Received Size Pointer Register: 0x0425 to 0x0427

#define S0_RX_RD 0x0428 // Socket 0: Rx Read Pointer: 0x0428 to 0x0429

#define TXBUFADDR 0x4000 // W5100 Send Buffer Base Address

#define RXBUFADDR 0x6000 // W5100 Read Buffer Base Address

// S0_MR values

#define MR_CLOSE 0x00 // Unused socket

#define MR_TCP 0x01 // TCP

#define MR_UDP 0x02 // UDP

#define MR_IPRAW 0x03 // IP LAYER RAW SOCK

#define MR_MACRAW 0x04 // MAC LAYER RAW SOCK

#define MR_PPPOE 0x05 // PPPoE

#define MR_ND 0x20 // No Delayed Ack(TCP) flag

#define MR_MULTI 0x80 // support multicating

// S0_CR values

#define CR_OPEN 0x01 // Initialize or open socket

#define CR_LISTEN 0x02 // Wait connection request in tcp mode(Server mode)

#define CR_CONNECT 0x04 // Send connection request in tcp mode(Client mode)

#define CR_DISCON 0x08 // Send closing reqeuset in tcp mode

#define CR_CLOSE 0x10 // Close socket

#define CR_SEND 0x20 // Update Tx memory pointer and send data

#define CR_SEND_MAC 0x21 // Send data with MAC address, so without ARP process

#define CR_SEND_KEEP 0x22 // Send keep alive message

#define CR_RECV 0x40 // Update Rx memory buffer pointer and receive data

// S0_SR values

#define SOCK_CLOSED 0x00 // Closed

#define SOCK_INIT 0x13 // Init state

#define SOCK_LISTEN 0x14 // Listen state

#define SOCK_SYNSENT 0x15 // Connection state

#define SOCK_SYNRECV 0x16 // Connection state

#define SOCK_ESTABLISHED 0x17 // Success to connect

#define SOCK_FIN_WAIT 0x18 // Closing state

#define SOCK_CLOSING 0x1A // Closing state

#define SOCK_TIME_WAIT 0x1B // Closing state

#define SOCK_CLOSE_WAIT 0x1C // Closing state

#define SOCK_LAST_ACK 0x1D // Closing state

#define SOCK_UDP 0x22 // UDP socket

#define SOCK_IPRAW 0x32 // IP raw mode socket

#define SOCK_MACRAW 0x42 // MAC raw mode socket

#define SOCK_PPPOE 0x5F // PPPOE socket

#define TX_BUF_MASK 0x07FF // Tx 2K Buffer Mask:

#define RX_BUF_MASK 0x07FF // Rx 2K Buffer Mask:

#define NET_MEMALLOC 0x05 // Use 2K of Tx/Rx Buffer

#define TCP_PORT 80 // TCP/IP Port

#define MAX_BUF 210

// ============================================== Project scoped variables ================================================

IO_REG_TYPE bitmask;

volatile IO_REG_TYPE *baseReg;

uint8_t scratchPad[2];

uint8_t buf[MAX_BUF]; // The character buffer in which the HTTP Put will be constructed

// ========================================================================================================================

void SPI_Write(uint16_t addr,uint8_t data) {

SPI_PORT &= ~(1<<SPI_CS); // Activate the CS pin

SPDR = WIZNET_WRITE_OPCODE; // Start Wiznet W5100 Write OpCode transmission

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPDR = (addr & 0xFF00) >> 8; // Start Wiznet W5100 Address High Bytes transmission

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPDR = addr & 0x00FF; // Start Wiznet W5100 Address Low Bytes transmission

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPDR = data; // Start Data transmission

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPI_PORT |= (1<<SPI_CS); // CS pin is not active

}

unsigned char SPI_Read(uint16_t addr) {

SPI_PORT &= ~(1<<SPI_CS); // Activate the CS pin

SPDR = WIZNET_READ_OPCODE; // Start Wiznet W5100 Read OpCode transmission

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPDR = (addr & 0xFF00) >> 8; // Start Wiznet W5100 Address High Bytes transmission

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPDR = addr & 0x00FF; // Start Wiznet W5100 Address Low Bytes transmission

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPDR = 0x00; // Send Dummy transmission for reading the data

while(!(SPSR & (1<<SPIF))); // Wait for transmission complete

SPI_PORT |= (1<<SPI_CS); // CS pin is not active

return(SPDR);

}

void W5100_Init(void)

{

// Ethernet Setup

const unsigned char mac_addr[] = {0x00, 0x1D, 0x0D, 0x2C, 0x55, 0x3D};

const unsigned char ip_addr[] = {192,168,11,8};

const unsigned char sub_mask[] = {255,255,255,0};

const unsigned char gtw_addr[] = {192,168,11,1};

const unsigned char cosm_addr[] = {216,52,233,121};

// Setting the Wiznet W5100 Mode Register: 0x0000

SPI_Write(MR,0x80); // MR = 0b10000000;

// Setting the Wiznet W5100 Gateway Address (GAR): 0x0001 to 0x0004

SPI_Write(GAR + 0,gtw_addr[0]);

SPI_Write(GAR + 1,gtw_addr[1]);

SPI_Write(GAR + 2,gtw_addr[2]);

SPI_Write(GAR + 3,gtw_addr[3]);

// Setting the Wiznet W5100 Source Address Register (SAR): 0x0009 to 0x000E

SPI_Write(SAR + 0,mac_addr[0]);

SPI_Write(SAR + 1,mac_addr[1]);

SPI_Write(SAR + 2,mac_addr[2]);

SPI_Write(SAR + 3,mac_addr[3]);

SPI_Write(SAR + 4,mac_addr[4]);

SPI_Write(SAR + 5,mac_addr[5]);

// Setting the Wiznet W5100 Sub Mask Address (SUBR): 0x0005 to 0x0008

SPI_Write(SUBR + 0,sub_mask[0]);

SPI_Write(SUBR + 1,sub_mask[1]);

SPI_Write(SUBR + 2,sub_mask[2]);

SPI_Write(SUBR + 3,sub_mask[3]);

// Setting the Wiznet W5100 IP Address (SIPR): 0x000F to 0x0012

SPI_Write(SIPR + 0,ip_addr[0]);

SPI_Write(SIPR + 1,ip_addr[1]);

SPI_Write(SIPR + 2,ip_addr[2]);

SPI_Write(SIPR + 3,ip_addr[3]);

// Setting the Wiznet W5100 RX and TX Memory Size (2KB),

SPI_Write(RMSR,NET_MEMALLOC);

SPI_Write(TMSR,NET_MEMALLOC);

// Setting the Wiznet to connect to the Cosm server port 80

SPI_Write(S0_DIPR + 0,cosm_addr[0]);

SPI_Write(S0_DIPR + 1,cosm_addr[1]);

SPI_Write(S0_DIPR + 2,cosm_addr[2]);

SPI_Write(S0_DIPR + 3,cosm_addr[3]);

SPI_Write(S0_DPORT,((TCP_PORT & 0xFF00) >> 8 ));

SPI_Write(S0_DPORT + 1,(TCP_PORT & 0x00FF));

SPI_Write(S0_PORT,((1 & 0xFF00) >> 8 )); // Set the source port to 1

SPI_Write(S0_PORT + 1,(1 & 0x00FF)); // Set the source port to 1

// Set the Wiznet to use TCP

SPI_Write(S0_MR,MR_TCP); // Set the mode to TCP

}

void UploadDataPoint(void) {

// Connect to the Cosm server and upload the data

SPI_Write(S0_CR,CR_OPEN);

while(SPI_Read(S0_CR));

do {

_delay_ms(1);

} while(SPI_Read(S0_SR)!=SOCK_INIT);

close(0);

SPI_Write(S0_MR,MR_TCP);

SPI_Write(S0_CR,CR_CONNECT); // Open Socket

// Wait for Opening Process

while(SPI_Read(S0_CR));

do {

_delay_ms(1);

} while(SPI_Read(S0_SR)!=SOCK_ESTABLISHED);

send(0,buf,strlen((char *)buf));

}

void close(uint8_t sock)

{

if (sock != 0) return;

// Send Close Command

SPI_Write(S0_CR,CR_CLOSE);

// Waiting until the S0_CR is clear

while(SPI_Read(S0_CR));

}

void disconnect(uint8_t sock)

{

if (sock != 0) return;

// Send Disconnect Command

SPI_Write(S0_CR,CR_DISCON);

// Wait for Disconecting Process

while(SPI_Read(S0_CR));

}

uint16_t send(uint8_t sock,const uint8_t *buf,uint16_t buflen)

{

uint16_t ptr,offaddr,realaddr,txsize,timeout;

if (buflen <= 0 || sock != 0) return 0;

// Make sure the TX Free Size Register is available

txsize=SPI_Read(SO_TX_FSR);

txsize=(((txsize & 0x00FF) << 8 ) + SPI_Read(SO_TX_FSR + 1));

timeout=0;

while (txsize < buflen) {

_delay_ms(1);

txsize=SPI_Read(SO_TX_FSR);

txsize=(((txsize & 0x00FF) << 8 ) + SPI_Read(SO_TX_FSR + 1));

// Timeout for approx 1000 ms

if (timeout++ > 1000) {

// Disconnect the connection

disconnect(sock);

return 0;

}

}

// Read the Tx Write Pointer

ptr = SPI_Read(S0_TX_WR);

offaddr = (((ptr & 0x00FF) << 8 ) + SPI_Read(S0_TX_WR + 1));

while(buflen) {

buflen--;

// Calculate the real W5100 physical Tx Buffer Address

realaddr = TXBUFADDR + (offaddr & TX_BUF_MASK);

// Copy the application data to the W5100 Tx Buffer

SPI_Write(realaddr,*buf);

offaddr++;

buf++;

}

// Increase the S0_TX_WR value, so it point to the next transmit

SPI_Write(S0_TX_WR,(offaddr & 0xFF00) >> 8 );

SPI_Write(S0_TX_WR + 1,(offaddr & 0x00FF));

// Now Send the SEND command

SPI_Write(S0_CR,CR_SEND);

// Wait for Sending Process

while(SPI_Read(S0_CR));

return 1;

}

uint8_t read_bit(void) {

IO_REG_TYPE mask=bitmask;

volatile IO_REG_TYPE *reg IO_REG_ASM = baseReg;

uint8_t r;

noInterrupts();

DIRECT_MODE_OUTPUT(reg, mask);

DIRECT_WRITE_LOW(reg, mask);

_delay_us(3);

DIRECT_MODE_INPUT(reg, mask); // let pin float, pull up will raise

_delay_us(10);

r = DIRECT_READ(reg, mask);

interrupts();

_delay_us(53);

return r;

}

uint8_t read() {

uint8_t bitMask;

uint8_t r = 0;

for (bitMask = 0x01; bitMask; bitMask <<= 1) {

if ( read_bit()) r |= bitMask;

}

return r;

}

void write_bit(uint8_t v) {

IO_REG_TYPE mask=bitmask;

volatile IO_REG_TYPE *reg IO_REG_ASM = baseReg;

if (v & 1) {

noInterrupts();

DIRECT_WRITE_LOW(reg, mask);

DIRECT_MODE_OUTPUT(reg, mask); // drive output low

_delay_us(10);

DIRECT_WRITE_HIGH(reg, mask); // drive output high

interrupts();

_delay_us(55);

}

else {

noInterrupts();

DIRECT_WRITE_LOW(reg, mask);

DIRECT_MODE_OUTPUT(reg, mask); // drive output low

_delay_us(65);

DIRECT_WRITE_HIGH(reg, mask); // drive output high

interrupts();

_delay_us(5);

}

}

void write(uint8_t v) {

uint8_t bitMask;

for (bitMask = 0x01; bitMask; bitMask <<= 1) write_bit( (bitMask & v)?1:0);

noInterrupts();

DIRECT_MODE_INPUT(baseReg, bitmask);

DIRECT_WRITE_LOW(baseReg, bitmask);

interrupts();

}

uint8_t reset(void) {

IO_REG_TYPE mask = bitmask;

volatile IO_REG_TYPE *reg IO_REG_ASM = baseReg;

uint8_t r;

uint8_t retries = 125;

noInterrupts();

DIRECT_MODE_INPUT(reg, mask);

interrupts();

// wait until the wire is high... just in case

do {

if (--retries == 0) return 0;

_delay_us(2);

} while ( !DIRECT_READ(reg, mask));

noInterrupts();

DIRECT_WRITE_LOW(reg, mask);

DIRECT_MODE_OUTPUT(reg, mask); // drive output low

interrupts();

_delay_us(500);

noInterrupts();

DIRECT_MODE_INPUT(reg, mask); // allow it to float

_delay_us(80);

r = !DIRECT_READ(reg, mask);

interrupts();

_delay_us(420);

return r;

}

int16_t ReadSensor(const uint8_t sensorIndex) {

write(0x55); // Choose ROM

for(uint8_t i = 0; i < 8; i++) write(Sensor[sensorIndex][i]);

write(READSCRATCH);

scratchPad[TEMP_LSB] = read();

scratchPad[TEMP_MSB] = read();

reset();

return (((int16_t)scratchPad[TEMP_MSB]) << 8) | scratchPad[TEMP_LSB];

}

// Converts the raw temperature from a DS18B20 directly to a string containing the temperature in °F

// avoids unnecessary floating point math, float variables, and casts

// TODO: May not work properly with temperatures below 32°F

void RawTempToString(uint16_t raw, char * buffer) {

uint32_t intTemp;

uint8_t numChars;

intTemp=raw*1125ul+320000ul; // Hold the temperature

if(raw<605 && raw>=0) { // We're looking at a positive number with two digits

numChars = 7;

}

else if (raw>=605) {

numChars = 8;

}

// Write the null termination, the first four digits, and then the decimal point

buffer[numChars--]='\0';

buffer[numChars--]=intTemp%10 + '0';

intTemp/=10;

buffer[numChars--]=intTemp%10 + '0';

intTemp/=10;

buffer[numChars--]=intTemp%10 + '0';

intTemp/=10;

buffer[numChars--]=intTemp%10 + '0';

intTemp/=10;

buffer[numChars--]='.';

// Continue writing the left of the decimal place until we run out of intTemp

do {

buffer[numChars--]=intTemp%10 + '0';

intTemp/=10;

} while (intTemp);

}

void itoa(long inp, char * buf) {

long temp = inp;

uint8_t numChars=0;

boolean isNegative=false;

// Check to see if there is a negative sign

if(temp<0){

isNegative=true;

numChars++;

temp*=-1;

}

do {

numChars++;

temp /= 10;

} while ( temp );

// Write the negative sign if present and the terminating null character

temp=inp;

buf[numChars]=0;

if(isNegative) {

temp*=-1;

buf[0]='-';

}

int i = numChars - 1;

do {

buf[i--] = temp%10 + '0';

temp /= 10;

} while (temp);

}

void BuildPut(uint16_t T1, uint16_t T2) {

// Convert raw temperatures into strings

char Temp1[8];

char Temp2[8];

RawTempToString(T1, (char *)Temp1);

RawTempToString(T2, (char *)Temp2);

// Set up data buffer to hold the csv data

char * dataBuffer[strlen(Sensor1)+strlen(Temp1)+strlen(Sensor2)+strlen(Temp2)+4];

strcpy((char *)dataBuffer,Sensor1);

strcat_P((char *)dataBuffer,PSTR(","));

strcat((char *)dataBuffer,Temp1);

strcat_P((char *)dataBuffer,PSTR("\n"));

strcat((char *)dataBuffer,Sensor2);

strcat_P((char *)dataBuffer,PSTR(","));

strcat((char *)dataBuffer,Temp2);

strcat_P((char *)dataBuffer,PSTR("\n"));

// Convert the length of the data buffer into a string

char dataLength[2];

itoa(strlen((char *)dataBuffer)-1,(char *)dataLength);

// Construct the HTTP Put

strcpy_P((char *)buf,PSTR("PUT /v2/feeds/"));

strcat((char *)buf,FEEDID);

strcat_P((char *)buf,PSTR(".csv HTTP/1.1\nHost: api.cosm.com\n"));

strcat_P((char *)buf,PSTR("X-ApiKey: "));

strcat((char *)buf,APIKEY);

strcat_P((char *)buf,PSTR("\nUser-Agent: "));

strcat((char *)buf,USERAGENT);

strcat_P((char *)buf,PSTR("\nContent-Length: "));

strcat((char *)buf,dataLength);

strcat_P((char *)buf,PSTR("\n\n"));

strcat((char *)buf,(char *)dataBuffer);

}

int main() {

// This code will only run once, after each powerup or reset of the board

// Set pin 3 to input

//pinMode(pin, INPUT); // This takes 136 bytes of sketch size

//DDRD = DDRD | B11110100; // This does the same thing and only takes 4 bytes of sketch size

// This does the same thing since pin 3 is set to input by default

bitmask = PIN_TO_BITMASK(pin);

baseReg = PIN_TO_BASEREG(pin);

SPI_DDR = (1<<PORTB3)|(1<<PORTB5)|(1<<PORTB2); // Set MOSI (PORTB3),SCK (PORTB5) and PORTB2 (SS) as output, others as input

SPI_PORT |= (1<<SPI_CS); // CS pin is not active

SPCR = (1<<SPE)|(1<<MSTR); // Enable SPI, Master Mode 0

#if DEBUG

Serial.begin(9600);

#endif

W5100_Init();

for (;;) {

// Request a temperature reading from all Dallas sensors on the OneWire bus

reset();

write(0xCC);

write(STARTCONVO);

_delay_ms(750); // Wait 750ms to allow for a 12-bit precision temperature reading to be taken by the DS18B20(s)

reset();

// Read the temperatures previously requested

int16_t rawTemperature1 = ReadSensor(0); // Read the first sensor

int16_t rawTemperature2 = ReadSensor(1); // Read the second sensor

BuildPut(rawTemperature1, rawTemperature2);

#if DEBUG

Serial.print((char *)buf);

#endif

UploadDataPoint();

_delay_ms(DELAY);

}

}