Hello everyone,

I recently started a cal clone. I thought I would post the build in order to hopefully give others who are apprehensive about building an electric brewery some confidence. As posted in the title i am the least handy person I know. Up until this project the tools I own could be listed : A drill (and bits) a craftsman socket set), a welder which I never used and sold, and a few basic tools. Im using this build to learn some hands on skills with tools, and hopefully end up with some good beer.

Here is the progress below:

Getting the 20 gallon Pots ready:

Cals kit:

SWIMBO HELPING!:

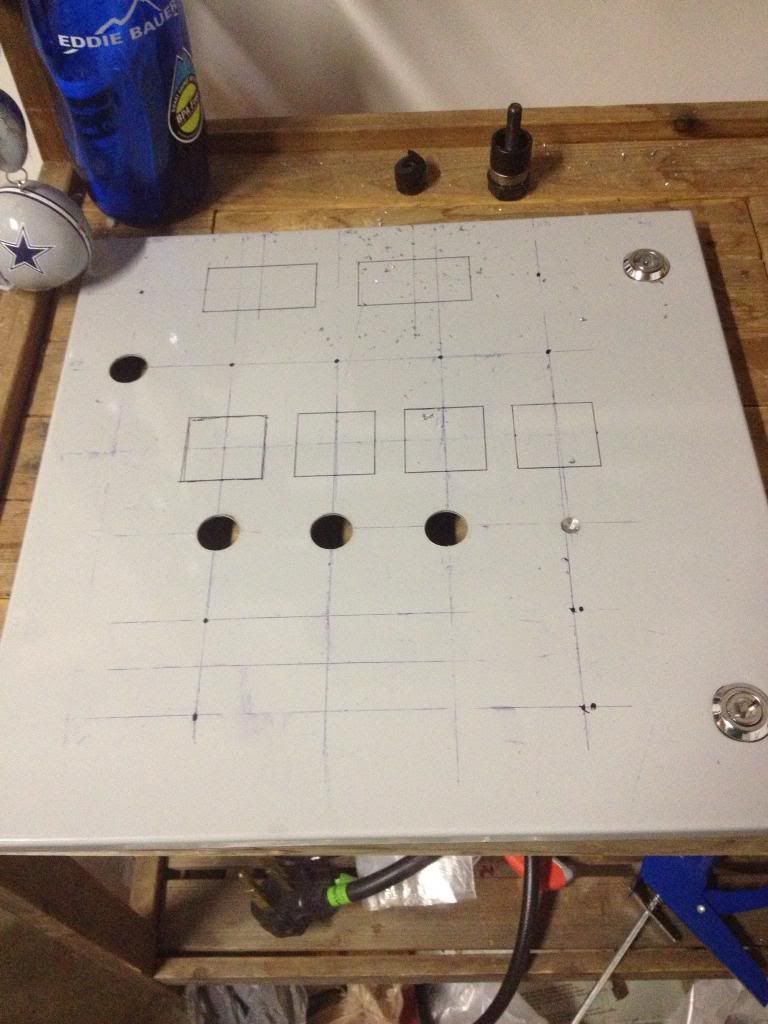

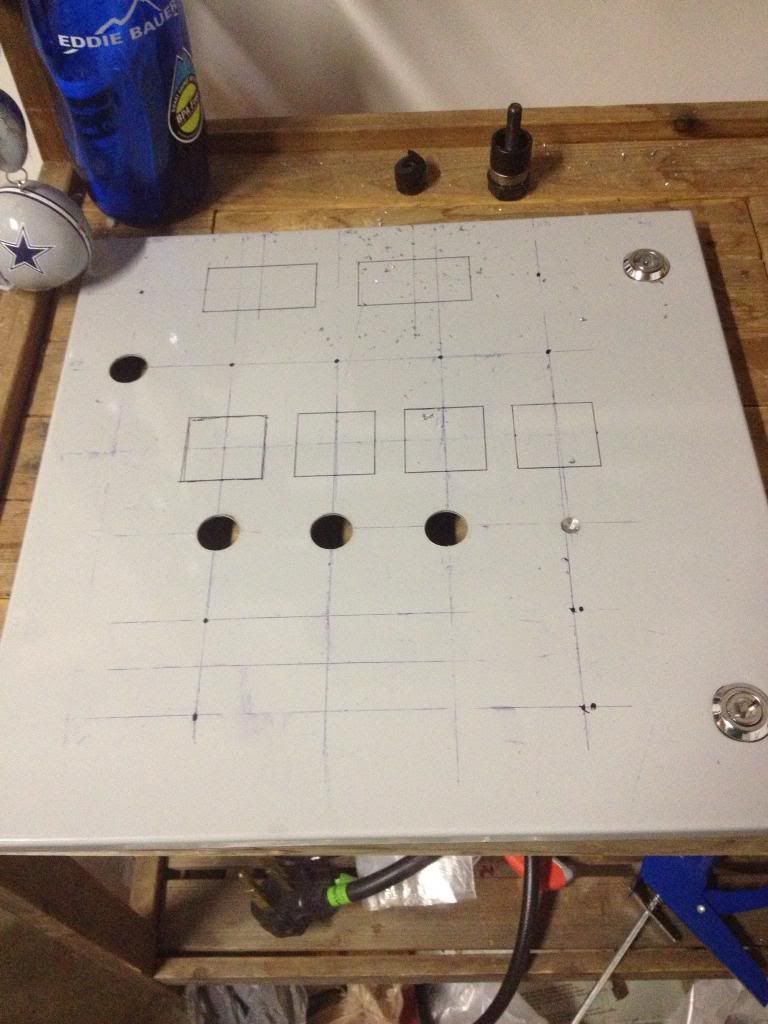

Measured and using a punch to make the holes.

Making some progress. Borrowed a compressor and cutting tool from my neighbor who is thrilled about the prospect of free beer.

The face is about done. I need to do some sanding and filling where I lost control of the dremel. Other than that I am extremely happy/ surprised with the progress.

May 20th - Update: Progress made. 3 trips to harbor freight and one to lows. Looks like i will have a ton of sanding and filing to get these pieces to fit.

May 23rd - FINALLY DONE FILING! The pieces fit! The only thing i had an issue with is on one of the top squares I made the thumb spots way to big. In cals pictures online they look really big hahaha. Not perfect but with the components in place the box is going to look great! Vary excited today.

I recently started a cal clone. I thought I would post the build in order to hopefully give others who are apprehensive about building an electric brewery some confidence. As posted in the title i am the least handy person I know. Up until this project the tools I own could be listed : A drill (and bits) a craftsman socket set), a welder which I never used and sold, and a few basic tools. Im using this build to learn some hands on skills with tools, and hopefully end up with some good beer.

Here is the progress below:

Getting the 20 gallon Pots ready:

Cals kit:

SWIMBO HELPING!:

Measured and using a punch to make the holes.

Making some progress. Borrowed a compressor and cutting tool from my neighbor who is thrilled about the prospect of free beer.

The face is about done. I need to do some sanding and filling where I lost control of the dremel. Other than that I am extremely happy/ surprised with the progress.

May 20th - Update: Progress made. 3 trips to harbor freight and one to lows. Looks like i will have a ton of sanding and filing to get these pieces to fit.

May 23rd - FINALLY DONE FILING! The pieces fit! The only thing i had an issue with is on one of the top squares I made the thumb spots way to big. In cals pictures online they look really big hahaha. Not perfect but with the components in place the box is going to look great! Vary excited today.