g-love

Well-Known Member

I started this with a bunch of questions in another thread because I was originally going to build a propane rig, but decided it'd be nice to use electric. I decided this for two main reasons: 1. I wasn't comfortable using propane inside (personal choice) and 2. I really like the idea of how quiet electric brewing is.

I have only done extract to this point, I tried an all grain BIAB one time that did not end well (my fault). I tend to jump into hobbies and go a little crazy with "stuff," and this has been no different. I have to say I've enjoyed the planning and building that I've done so far as much if not more than brewing in general.

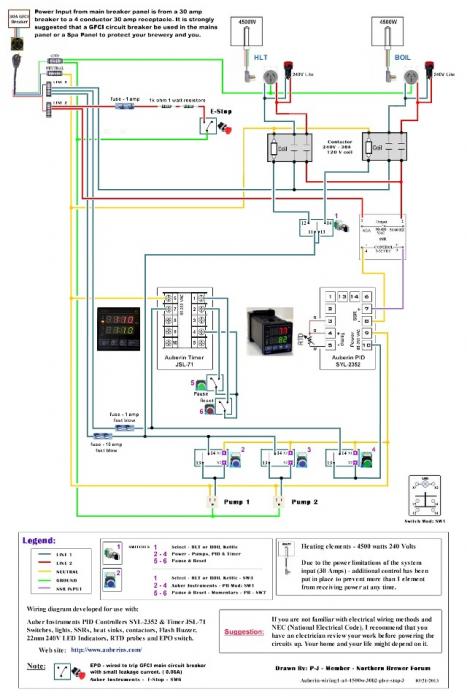

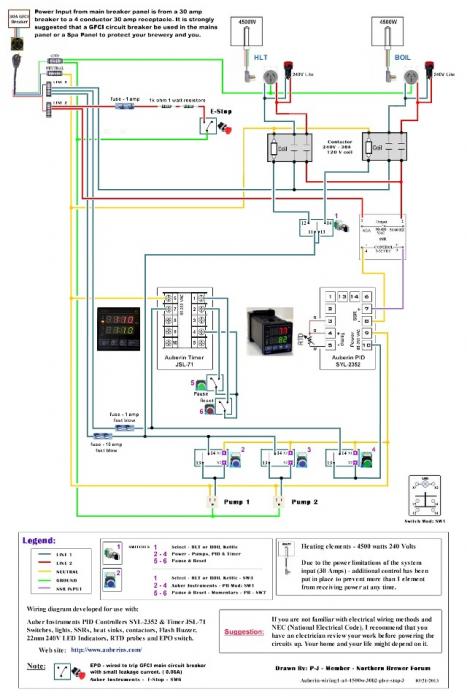

My build here is a 3 vessel e-herms build with (2) 4500 watt elements. I already had a basic stand built to accomodate the propane set up I was going with, so I am using that. It's overbuilt, but whatever. I took the measurements from jlandin's propane build and I really liked his idea of wanting to keep everything within the plane of the stand itself for storage. I build a brew closet in my garage that this slides into perfectly when I am not using it.

The following pics show the final wiring diagram (THANKS P-J!) that I went with and the build of the stand itself. That's where I am at this point. I've collected all of my parts, with the exception of a few odds and ends. This will be a slow one, but I'll keep this updated as I go.

I have only done extract to this point, I tried an all grain BIAB one time that did not end well (my fault). I tend to jump into hobbies and go a little crazy with "stuff," and this has been no different. I have to say I've enjoyed the planning and building that I've done so far as much if not more than brewing in general.

My build here is a 3 vessel e-herms build with (2) 4500 watt elements. I already had a basic stand built to accomodate the propane set up I was going with, so I am using that. It's overbuilt, but whatever. I took the measurements from jlandin's propane build and I really liked his idea of wanting to keep everything within the plane of the stand itself for storage. I build a brew closet in my garage that this slides into perfectly when I am not using it.

The following pics show the final wiring diagram (THANKS P-J!) that I went with and the build of the stand itself. That's where I am at this point. I've collected all of my parts, with the exception of a few odds and ends. This will be a slow one, but I'll keep this updated as I go.