So when batch sparging, all the stuff you read about the grain bed being at least so many inches and no more than so many inches does not matter?

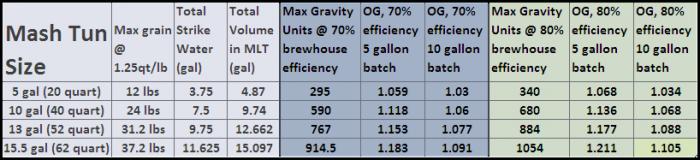

I'm asking because I have a 48 qt rectangular cooler that is very clean that I could use to build a lauter tun, but I am afraid that it will be too large since I am only planning on 5 gallon batches with OGs in the 40s to 50s.

You are correct...the traditional advice about grain bed depth does not relate to batch sparging. I've made 426 5 gal. batches in a 48 qt. cooler over the last 14+ years. If it didn't work I would have switched to something else a long time ago!