Stephonovich

Well-Known Member

So, I'm not hugely interested in building a full on automated build; plus Kal's system is pretty solid looking.

What I would like, however, is to do a small automated water measuring system for the HLT, and possibly to flow balance for fly sparging.

I found these flow meters, which while perhaps not the fanciest things (water makes turbine go roundy-roundy, causes pulses via Hall Effect), look like they'd work for pre-BK stuff. 80C is 176F, which is more than I can foresee putting into the MT. 25 L/min is about 6.6 GPM; again, more than I'll be pumping.

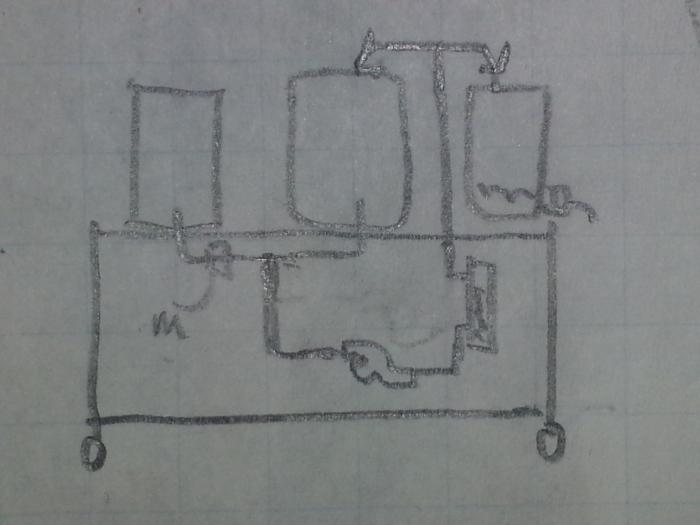

I see having an isolation valve upstream of a solenoid valve, then the flow meter. HLT pump output would also go to a flow meter, with a solenoid valve. An Arduino or RPi would control the solenoids, with an input keypad and LED/LCD screen. Some simple logic would suffice:

Punch in your desired maximum water volume you need.

Program adds in x% for losses.

Cold water solenoid opens until it reaches your volume, then shuts.

Punch in your initial mash volume.

As the Kal panel is maintaining temps for us, once we're at mash temp, start the water flow.

The program already has stored that we've heated up the water, so it knows to open the HLT output valves, and shuts once we reach initial volume.

Fly sparging would require a MT output flow meter as well to flow balance.

For the cold water inlet, I think I'd go with one of OSCSYS's motorized ball valves, to handle the pressure. For the others, since I'd be using silicon tubing, and March pumps only put out 5 psi at best, I'm thinking of building a linear actuator pinch valve, pull on power. As long as I can find one with adequate spring pressure to shut off flow when de-energized, this seems to be the cheapest way to control flow. Also, if you put small bends into the tubing, and with the pump off, I don't see leakage being much of an issue; at least not HLT --> MT.

Thoughts?

What I would like, however, is to do a small automated water measuring system for the HLT, and possibly to flow balance for fly sparging.

I found these flow meters, which while perhaps not the fanciest things (water makes turbine go roundy-roundy, causes pulses via Hall Effect), look like they'd work for pre-BK stuff. 80C is 176F, which is more than I can foresee putting into the MT. 25 L/min is about 6.6 GPM; again, more than I'll be pumping.

I see having an isolation valve upstream of a solenoid valve, then the flow meter. HLT pump output would also go to a flow meter, with a solenoid valve. An Arduino or RPi would control the solenoids, with an input keypad and LED/LCD screen. Some simple logic would suffice:

Punch in your desired maximum water volume you need.

Program adds in x% for losses.

Cold water solenoid opens until it reaches your volume, then shuts.

Punch in your initial mash volume.

As the Kal panel is maintaining temps for us, once we're at mash temp, start the water flow.

The program already has stored that we've heated up the water, so it knows to open the HLT output valves, and shuts once we reach initial volume.

Fly sparging would require a MT output flow meter as well to flow balance.

For the cold water inlet, I think I'd go with one of OSCSYS's motorized ball valves, to handle the pressure. For the others, since I'd be using silicon tubing, and March pumps only put out 5 psi at best, I'm thinking of building a linear actuator pinch valve, pull on power. As long as I can find one with adequate spring pressure to shut off flow when de-energized, this seems to be the cheapest way to control flow. Also, if you put small bends into the tubing, and with the pump off, I don't see leakage being much of an issue; at least not HLT --> MT.

Thoughts?