GrantH

Well-Known Member

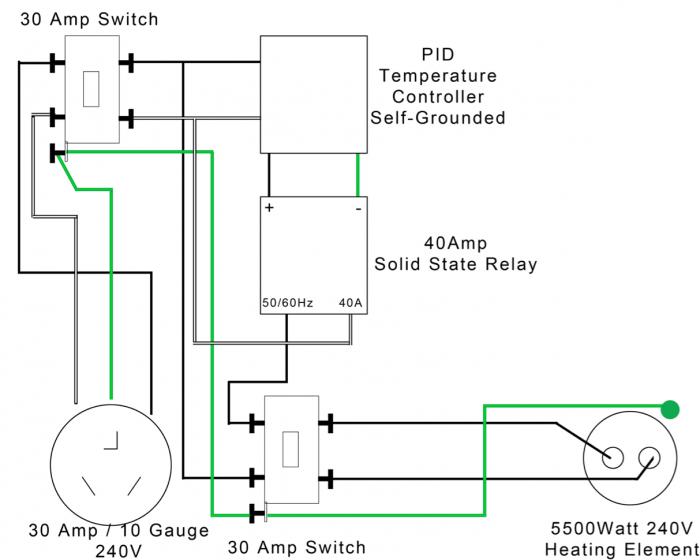

I'm doing a build for a RIMS system where I only need to get power to/from the temp probe and element. I know this is easy to most, but can I get some help please? I know a lot of you guys are better suited to help me through it than I am to try it myself.

So far, my plan is:

1/16 DIN Auber SYL-2352 (via TheElectricBrewery recommendation)

http://www.auberins.com/index.php?main_page=product_info&products_id=3

25A SSR

http://www.auberins.com/index.php?main_page=product_info&products_id=9

2.5" 1/2 NPT PT-100 RTD Sensor

http://www.auberins.com/index.php?m...ducts_id=261:981f97979ddaddfbae3363f4386c9002

I'm thinking I will run a 1500w element on 120v. I'd also like a power button to give main power but also a killswitch/safety switch if possible. That way both have to be tripped to power up, but I can kill power with the kill switch. Is that possible? Also, I need pump wiring, but I don't want to ask for too much!

Is there a similar diagram already out there?

So far, my plan is:

1/16 DIN Auber SYL-2352 (via TheElectricBrewery recommendation)

http://www.auberins.com/index.php?main_page=product_info&products_id=3

25A SSR

http://www.auberins.com/index.php?main_page=product_info&products_id=9

2.5" 1/2 NPT PT-100 RTD Sensor

http://www.auberins.com/index.php?m...ducts_id=261:981f97979ddaddfbae3363f4386c9002

I'm thinking I will run a 1500w element on 120v. I'd also like a power button to give main power but also a killswitch/safety switch if possible. That way both have to be tripped to power up, but I can kill power with the kill switch. Is that possible? Also, I need pump wiring, but I don't want to ask for too much!

Is there a similar diagram already out there?