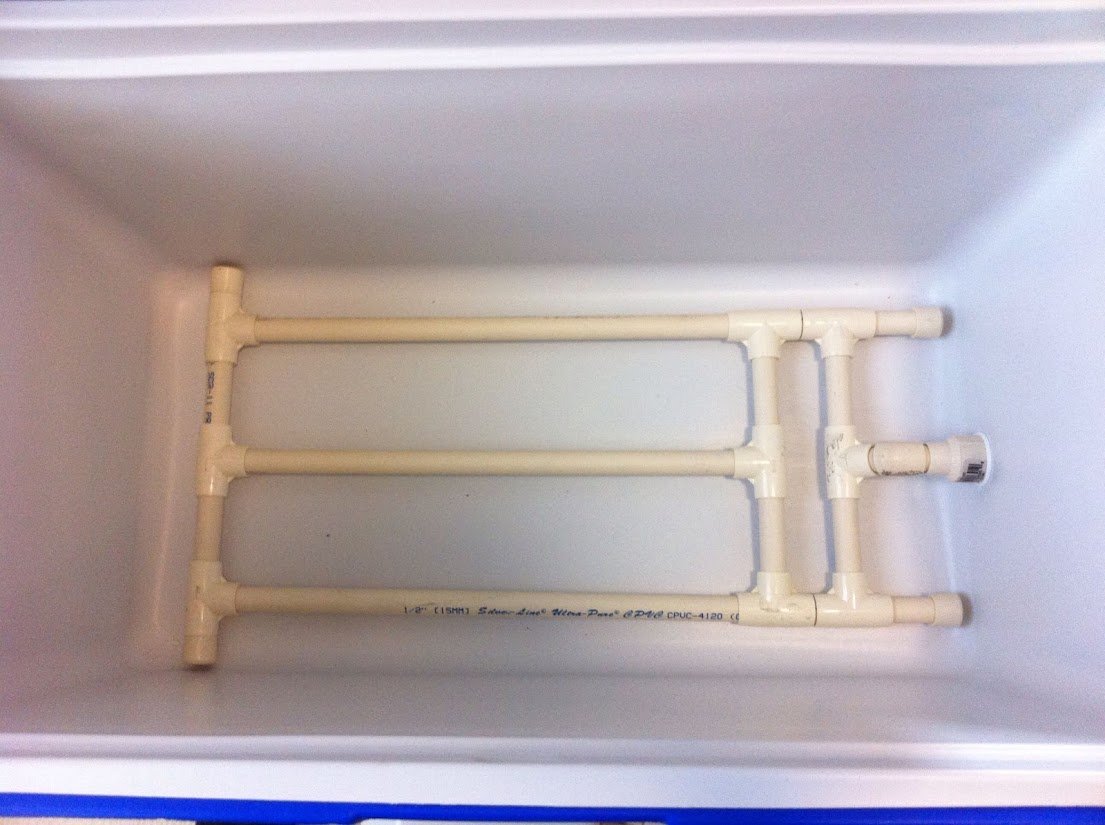

Yeah I used the cpvc 1/2 npt to slip fitting > 45 street > the t slips right on the street end of that. it rested perfectly in the bottom. I couldn't have asked for a better fit. I think it looks cleaner than a whole bunch of slits too, but we'll see how it functions. I'm going to do a batch in the next couple weeks and I'll let you know how it goes.

Thanks! Looks very good and simple. Still using a stainless bulkhead fitting and valve, right?

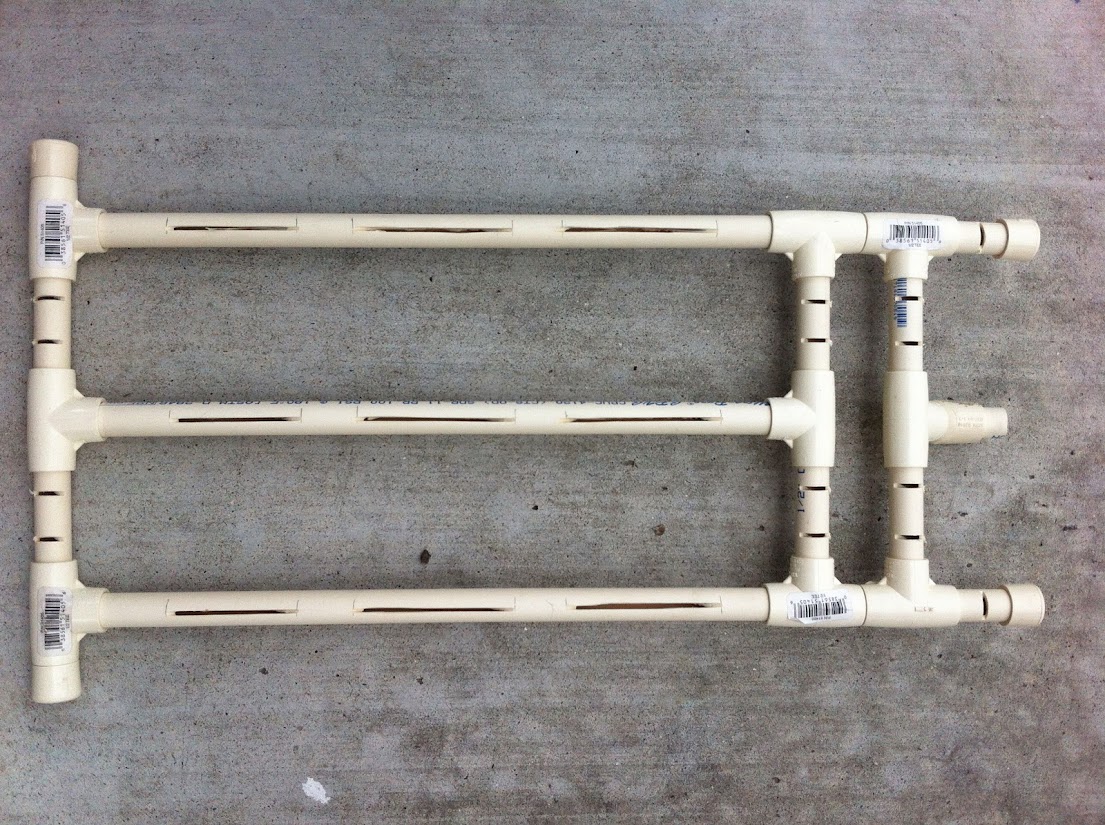

The only thing I see that may need attention is that the long slots as they are don't have a very large aggregate "open area" all together, compared to cross slits. Maybe another 2 sets of slots, one on each bottom quadrant of the tube, say 1/8" above the very bottom with an off-set, set could be added. Only one way to find out.