Just a build thread for my pump in a toolbox project. Feedback always appreciated.

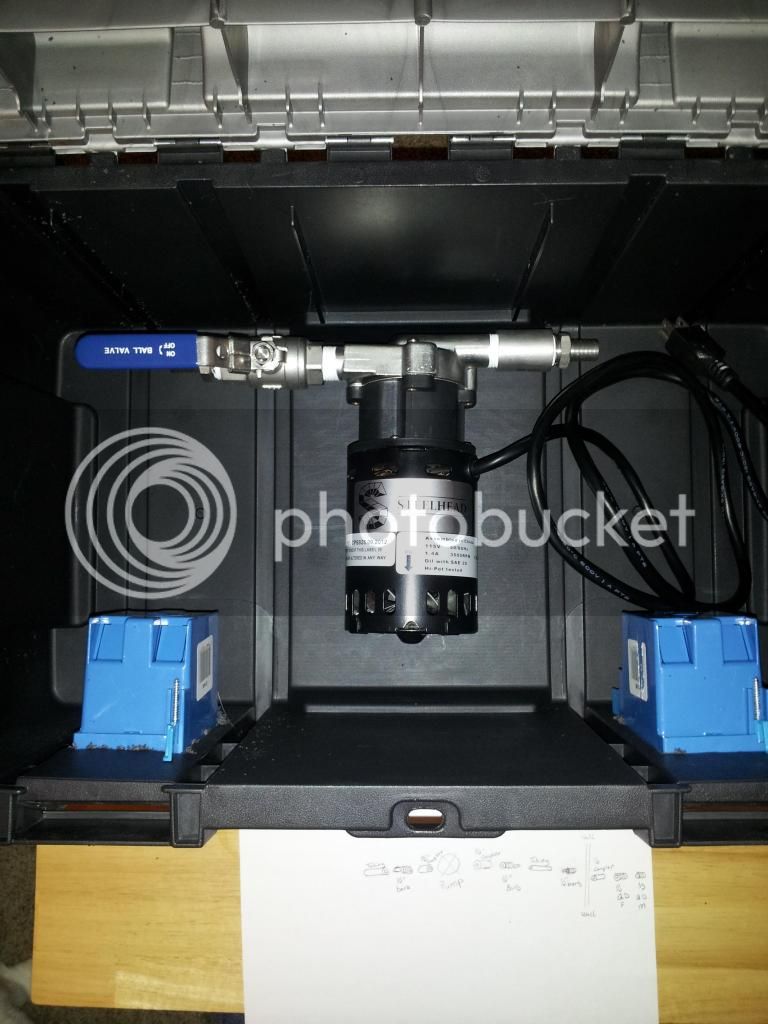

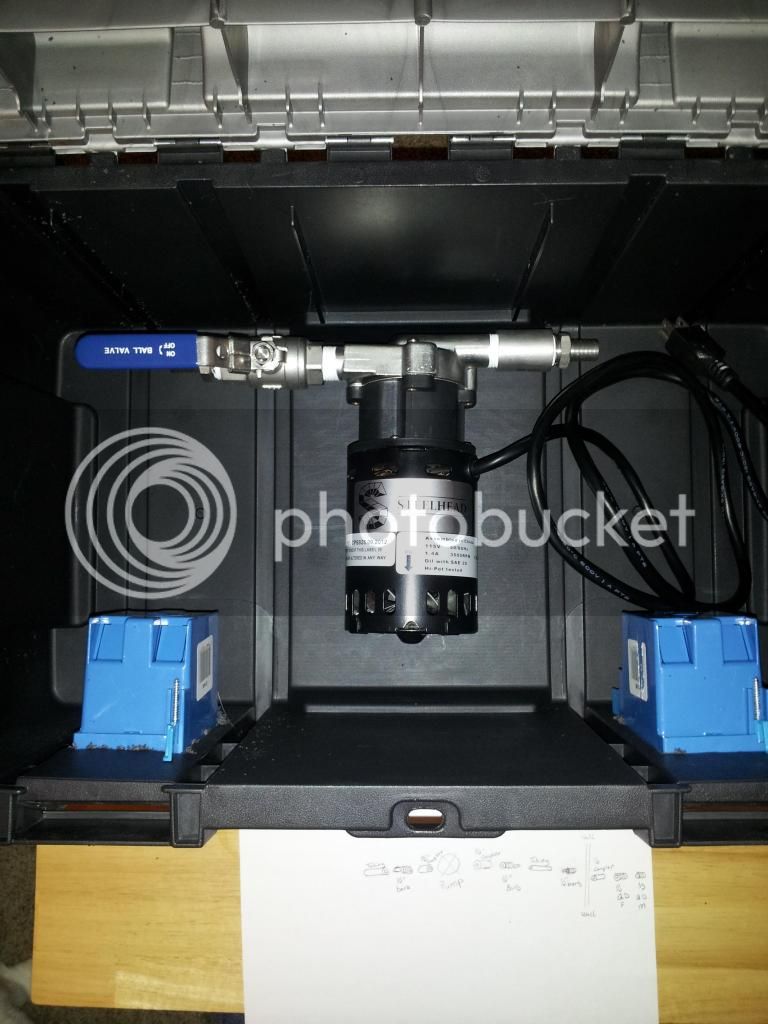

Here we go. My first purchase after a bonus at work starting burning a hole in my pocket.

Went to HomeDepot and found a tool box that looked perfect for the idea I had going. Brought it home and started hacking away to make the holes for the gang boxes.

Lesson learned on the first hole. The saw I had was not the best tool. On the second hole I drilled lots of holes around the outline the gang box then used a razor blade to cut and clean the edges. That made a perfect fit.

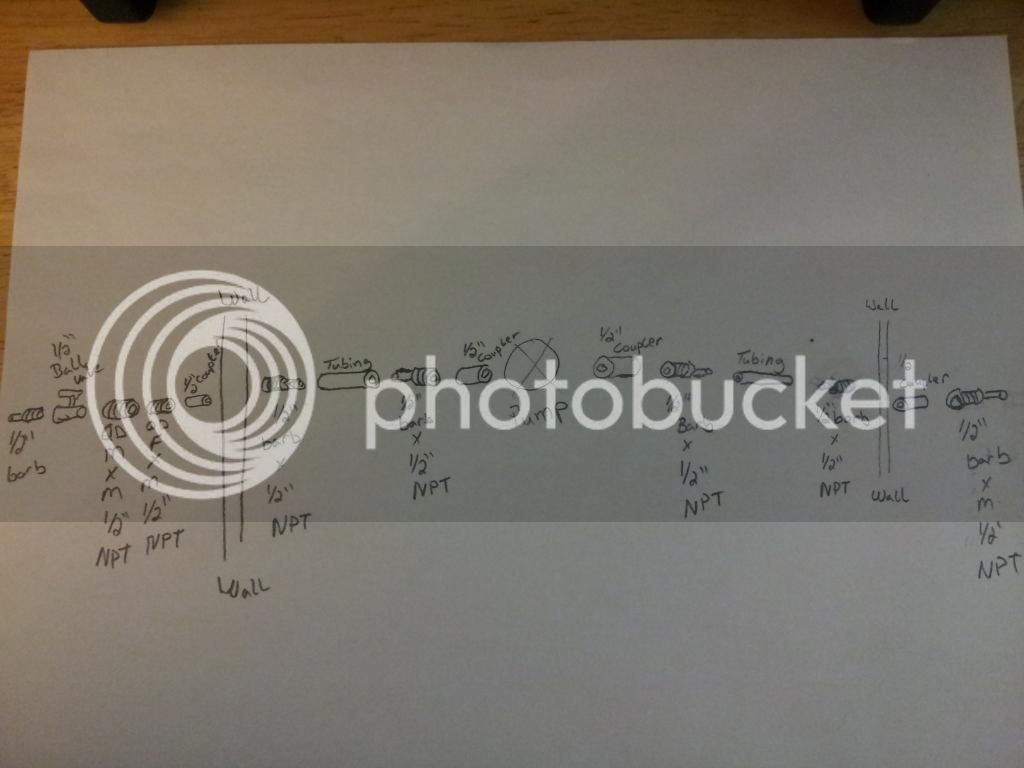

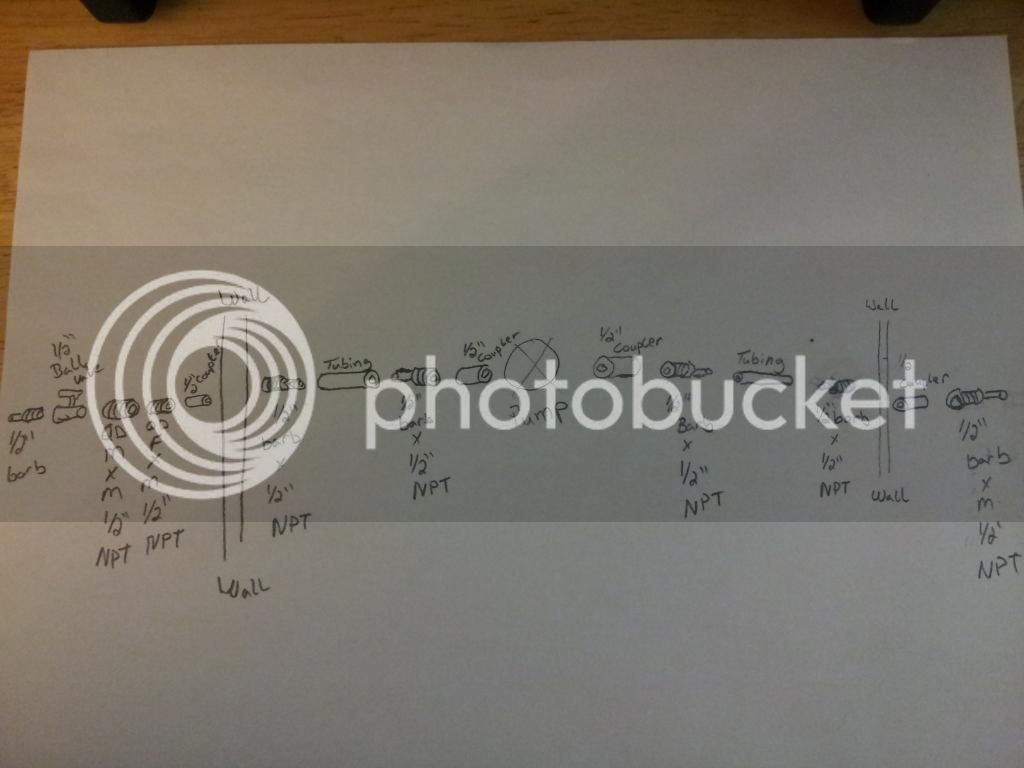

Time to map out the plumbing.

This is what I came up with. Im not sure about having a ball valve on a quick disconnect, but I would like to be able to disconnect it and store in the box. Also considering the quick disconnects for the inlet side.

Now I have to wait till Monday to buy the rest of the fittings.

Thoughts?

Here we go. My first purchase after a bonus at work starting burning a hole in my pocket.

Went to HomeDepot and found a tool box that looked perfect for the idea I had going. Brought it home and started hacking away to make the holes for the gang boxes.

Lesson learned on the first hole. The saw I had was not the best tool. On the second hole I drilled lots of holes around the outline the gang box then used a razor blade to cut and clean the edges. That made a perfect fit.

Time to map out the plumbing.

This is what I came up with. Im not sure about having a ball valve on a quick disconnect, but I would like to be able to disconnect it and store in the box. Also considering the quick disconnects for the inlet side.

Now I have to wait till Monday to buy the rest of the fittings.

Thoughts?