el_caro

Well-Known Member

- Joined

- Feb 3, 2011

- Messages

- 606

- Reaction score

- 35

Nicely done. You're OK my friend. I wouldn't bother telling you so if this thread weren't already cluttered enough though.

BTW, Subbed:rockin::rockin:

What is SUBBED?

Nicely done. You're OK my friend. I wouldn't bother telling you so if this thread weren't already cluttered enough though.

BTW, Subbed:rockin::rockin:

What is SUBBED?

tonyc318 said:Just pitched us-05 into a batch last night. 12 hours later there is a little foam starting to form on the top. Have the temp set at 65. Might go ahead and raise it to 66 for a middle of the road between your 64 and 68. Seems like a pretty standard temp for this yeast anyways.

pfgonzo said:You can use either a thermowell directly into the liquid, or tape/insulate the temperature probe to the side of the fermenter. Either method will get you the temperature of the fermentation itself, as opposed to ambient air. If you set the controller to 63, you will keep the liquid at 63 (plus or minus whatever your swing setting is).

+1 I tape the probe to the side of the vessel under a folded up old shirt. Does the job very well.

Golfduke, remind me: Are you using three separate temp controllers to monitor/maintain temperature?

The 60 degree batch is in a foamed out basement chamber. My basement stays at 56 degrees in the winter. I have a Lasko personal space heater in the chamber attached to a Johnson controller with the temp probe insulated and taped to the side of the carboy.

The 64 and 68 batch are done inside of a fridge. An STC1000 keeps it at 64, while I use a heat wrap for reptiles on the 68 degree fermentor with a probe inside of a thermowell and another johnson controller controlling that one.

So, essentially 3 controllers, 2 chambers, 3 different fermentation temps.

This thread has jumped the shark...

If your temp is set at 66 isn't your fermentation temp going to be in the 70's? In just curious because I don't understand how ppl use temp controllers. If you set your temp controlled set up to 63 say. How do you still know what the actual fermentation temp is ?? Even then doesn't the temp rise and fall as peak fermentation hits the gradually decreases?

I use a plastic gallon container (the ones that I get when I buy RO water at the grocery store) filled with water with the temp controller probe in that. The water, and it's change in temp, will be right around the same as the wort.

golfduke said:That above post came off really snobby, sorry. That wasn't my intent. You can make excellent beer without thermowells or even active temp control... In fact, I still ferment in my basement stairwell for some belgians without any control and think they come out really well.

I was just more commenting on the scientific basis of measuring fermentation temp most accurately.

FightingBob said:Yeah, my beer tastes pretty good and I've brewed with constancy, even my lagers. I also can fit two buckets/carboys/better bottles in my chest freezer-turned fermentation chamber. With only one prob, the gallon of water seemed like the best compromise. Def better than the swamp cooler i used to use. If I ever go pro, I'll have more precise temp control.

In another thread I did the math and figured out that my 5% ABV house ale will produce about 820 BTU or a 20º F total energy absorption. Over the space of let's say a week this doesn't add up to my 5 gallons of beer being 6-8 degrees warmer than ambient.Second, and more importantly, fermentation is surprisingly exothermic. I've measured 10+ degree increases in wort from ambient chamber temps during particularly vigorous fermentations. As an average, 6-8 degrees is more normal.

In another thread I did the math and figured out that my 5% ABV house ale will produce about 820 BTU or a 20º F total energy absorption. Over the space of let's say a week this doesn't add up to my 5 gallons of beer being 6-8 degrees warmer than ambient.

I'm not calling you a liar, just curious what your conditions were that caused this? I've never seen more than a degree or two of difference provided there was some air circulation.

In another thread I did the math and figured out that my 5% ABV house ale will produce about 820 BTU or a 20º F total energy absorption. Over the space of let's say a week this doesn't add up to my 5 gallons of beer being 6-8 degrees warmer than ambient.

I'm not calling you a liar, just curious what your conditions were that caused this? I've never seen more than a degree or two of difference provided there was some air circulation.

Is it possible in that closed space, even with it being cooled, that there's not enough air movement to keep the carboy surface cooled? It's only 240 watts of energy but that's probably a lot in a small space with no air movement. You say fridge - is that a late-model fridge with a fan or ore like an old static cone?I don't doubt your calculations, but my thermometers don't lie. I'm a biochemist by trade... I've witnessed several (I.e. more than 50%) of my beers go higher than 6 degrees above ambient, and thats across a range. Most of my beers are in the 1.050's. this is in a closed fridge with a Thermowell and a ptc100 style temp probe and readout in the beer and air in the fridge. Do all the thermo calculations you want, but my results are my results. I'm not trying to sway anyone's opinion one way or the other, just posting my experiences.

There is one reason you might want to put the probe into a smaller volume of water. The temperature changes faster, so the compressor will cycle more often, making smaller corrections.

As an example, say you have a thermowell with a controller set for 62 F with a one degree differential. When the beer gets up to 63F the compressor kicks in to cool it down to 62F. That’s going to take a while. The compressor is not designed for that, it could burn up.

If you measure the gallon jug temperature, the compressor will kick on earlier and more often. The regulation will be tighter.

It won’t automatically compensate for the fermentation heat, but you can eyeball it and guess.

Is it possible in that closed space, even with it being cooled, that there's not enough air movement to keep the carboy surface cooled? It's only 240 watts of energy but that's probably a lot in a small space with no air movement. You say fridge - is that a late-model fridge with a fan or ore like an old static cone?

A beer in the 1.050's is close to the one for which I did the calculations. I get that your thermometer does not lie but then again you know the rules of matter and energy. Gotta come from somewhere (or not be allowed to go somewhere in this case).

It's all very interesting for discussion fodder.

In another thread I did the math and figured out that my 5% ABV house ale will produce about 820 BTU or a 20º F total energy absorption. Over the space of let's say a week this doesn't add up to my 5 gallons of beer being 6-8 degrees warmer than ambient.

I'm not calling you a liar, just curious what your conditions were that caused this? I've never seen more than a degree or two of difference provided there was some air circulation.

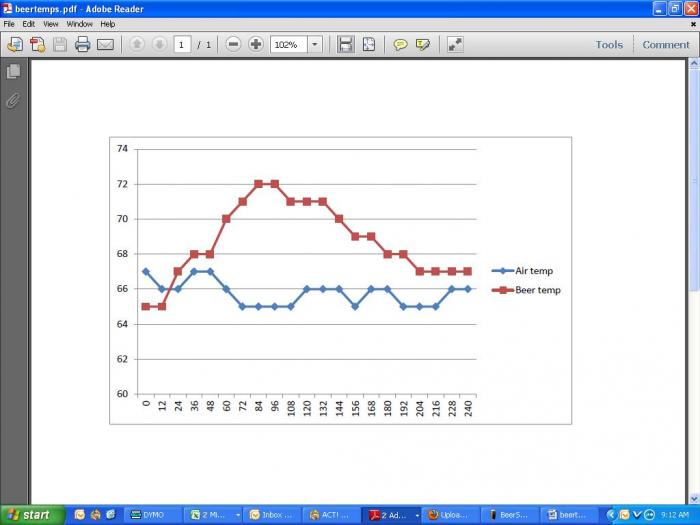

That is pretty interesting. Especially the continued difference at the end (I assume they were calibrated beforehand). Not what I would have expected.Here is something sort of useful as well. This was the last belgian I did without any temp control at all. I had just read Brew Like a Monk, and noted that Jolly Pumpkin and Russian River just pitch at x temp and let it go unmonitored through 90% of fermentation. I hooked up 2 ptc probes to monitor air temp and beer temp inside of a thermowell and made a graph...

These should be ready to pour on Sunday... they're in the keezer and tapped, just waiting for more bubbles.

I'm on a service call for work and won't be back until tomorrow night... I'm interested in the results.

Enter your email address to join: