scottvin

Well-Known Member

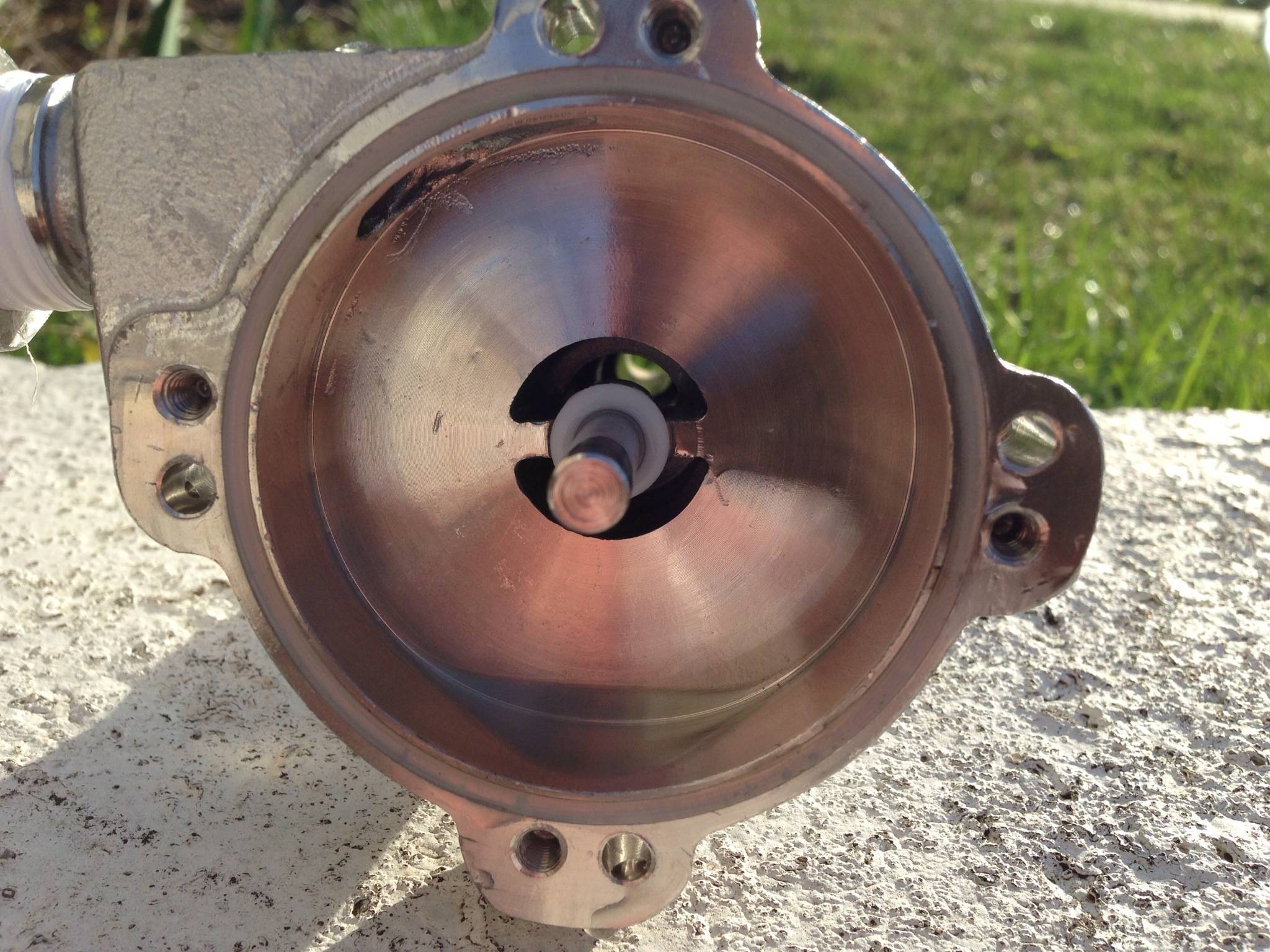

I decided on the center inlet chugger pump and I am going to use it for the first time this weekend - I'm very excited!

However, I have a few questions.

Is it ok to let the wort flow into the pump with pump on and the output ball valve closed?

Should I clean it out with a oxyclean solution before first use?

When should I start whirlpooling to wort?

When cooling how long should I whirlpool the wort through the place chiller back into the BK?

Thanks for the help!

However, I have a few questions.

Is it ok to let the wort flow into the pump with pump on and the output ball valve closed?

Should I clean it out with a oxyclean solution before first use?

When should I start whirlpooling to wort?

When cooling how long should I whirlpool the wort through the place chiller back into the BK?

Thanks for the help!