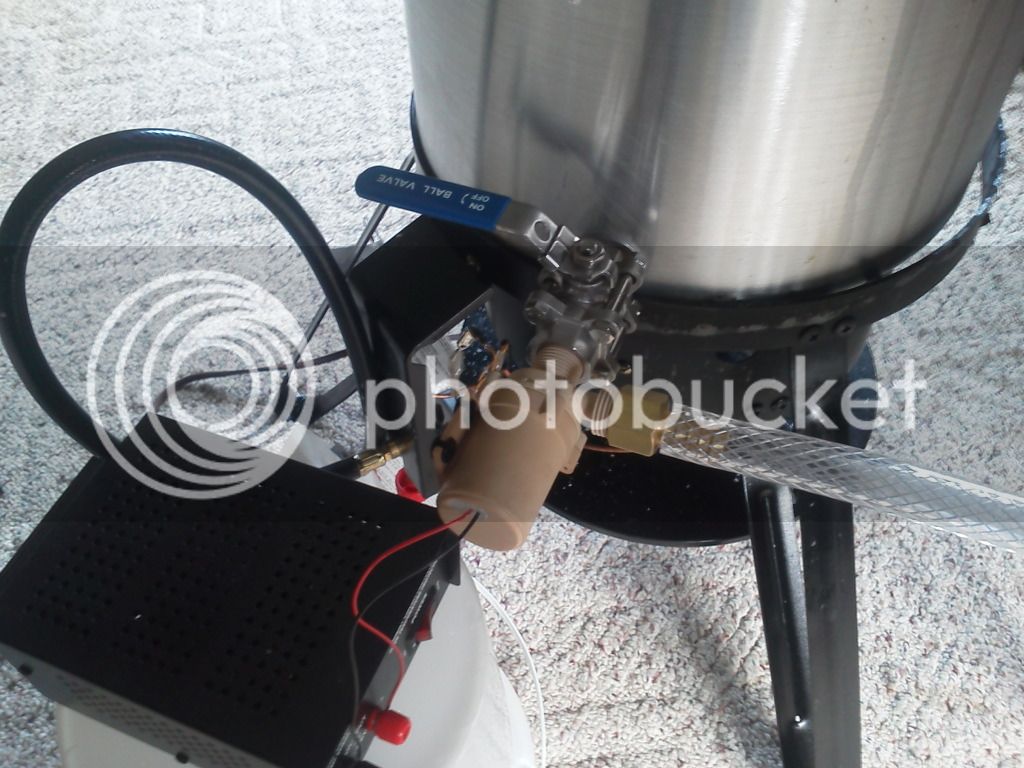

I received my tan ebay pump yesterday. Small is an understatement. I just can't get over how tiny this thing is. I was also surprised by the material its made out of. I was expecting a regular plastic that is cheap and semi-soft feeling, like most of the goods coming from china, but the material this pump is made out of is very hard, and almost feels ceramic. It feels tough as nails, but maybe a bit brittle (again, the best I can describe is it feels like ceramic). I had doubts about connecting this in line on my ball valve on the kettle, but now I feel a little better about it.